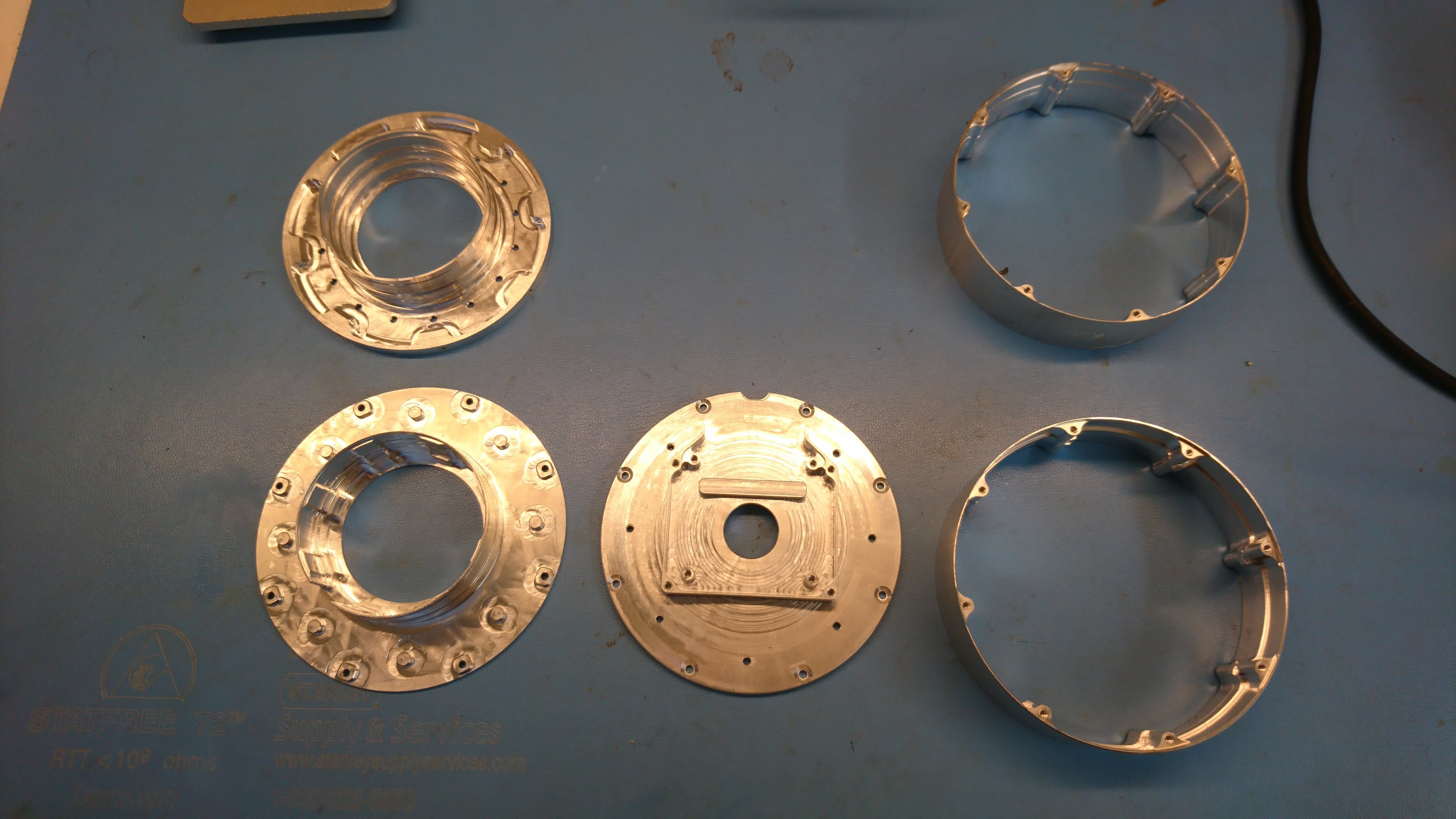

Ground truth torque testing for qdd100

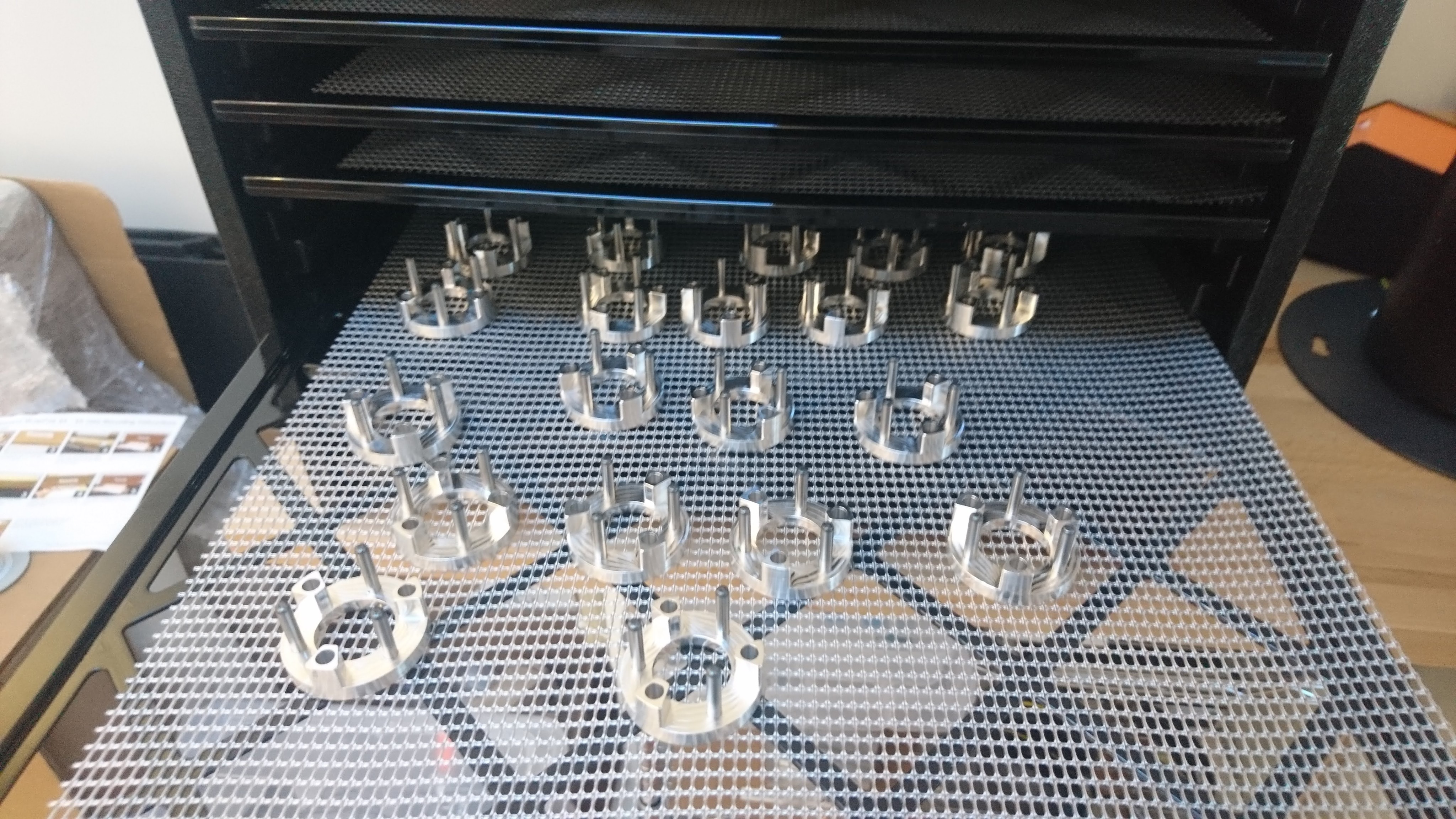

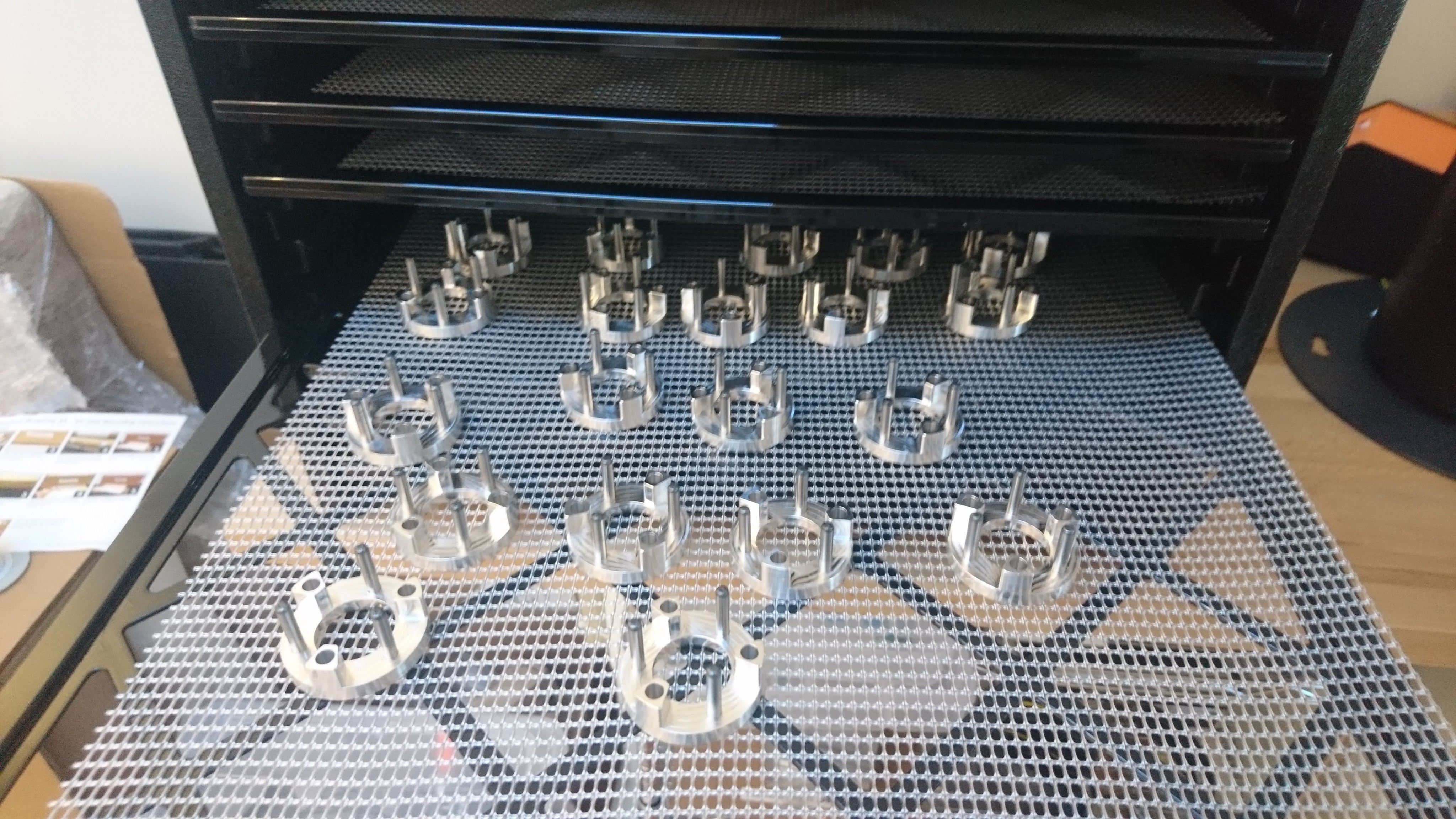

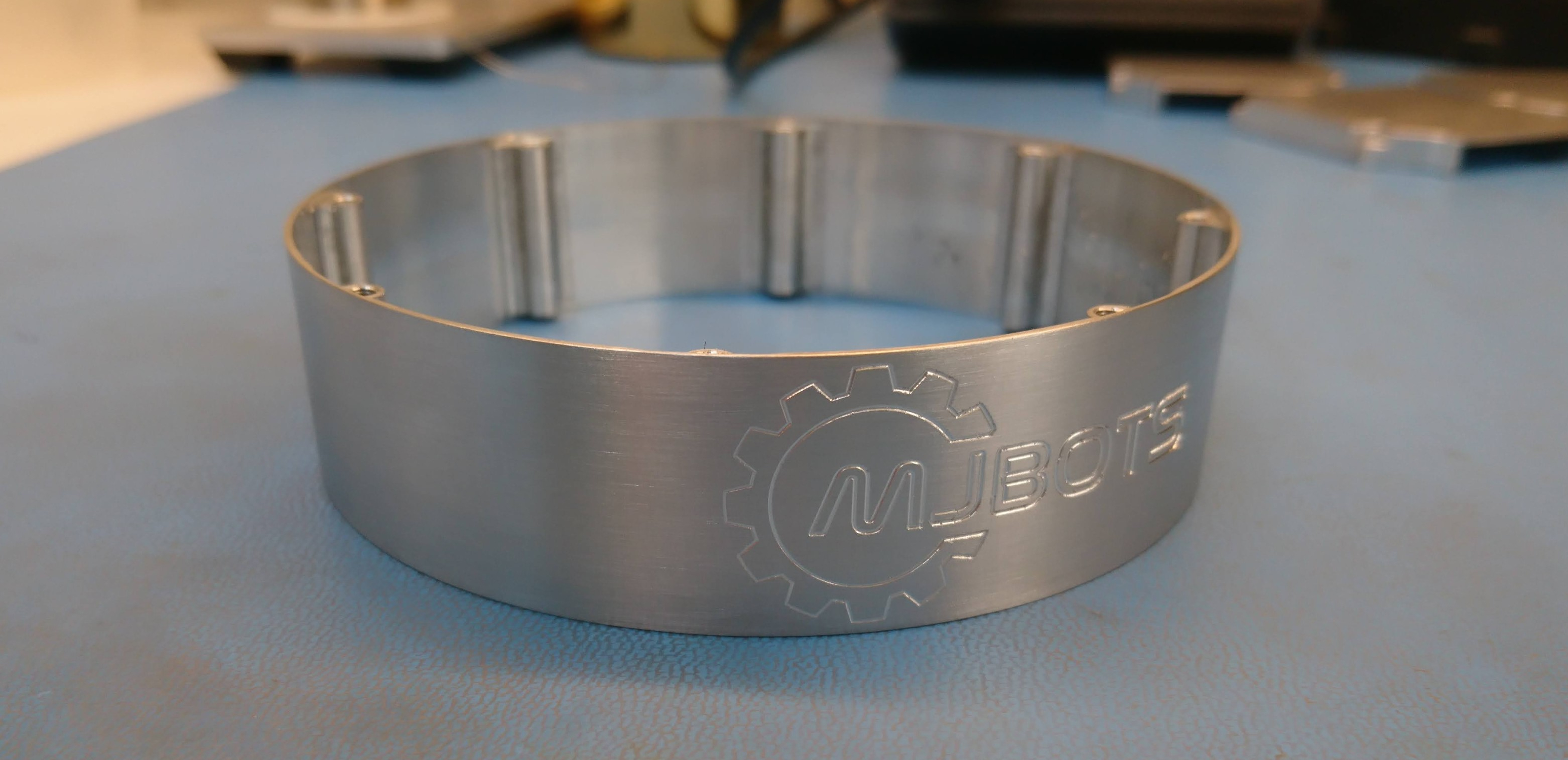

First, a limited number of qdd100 servos are available for sale to beta testers! Check them out at mjbots.com.

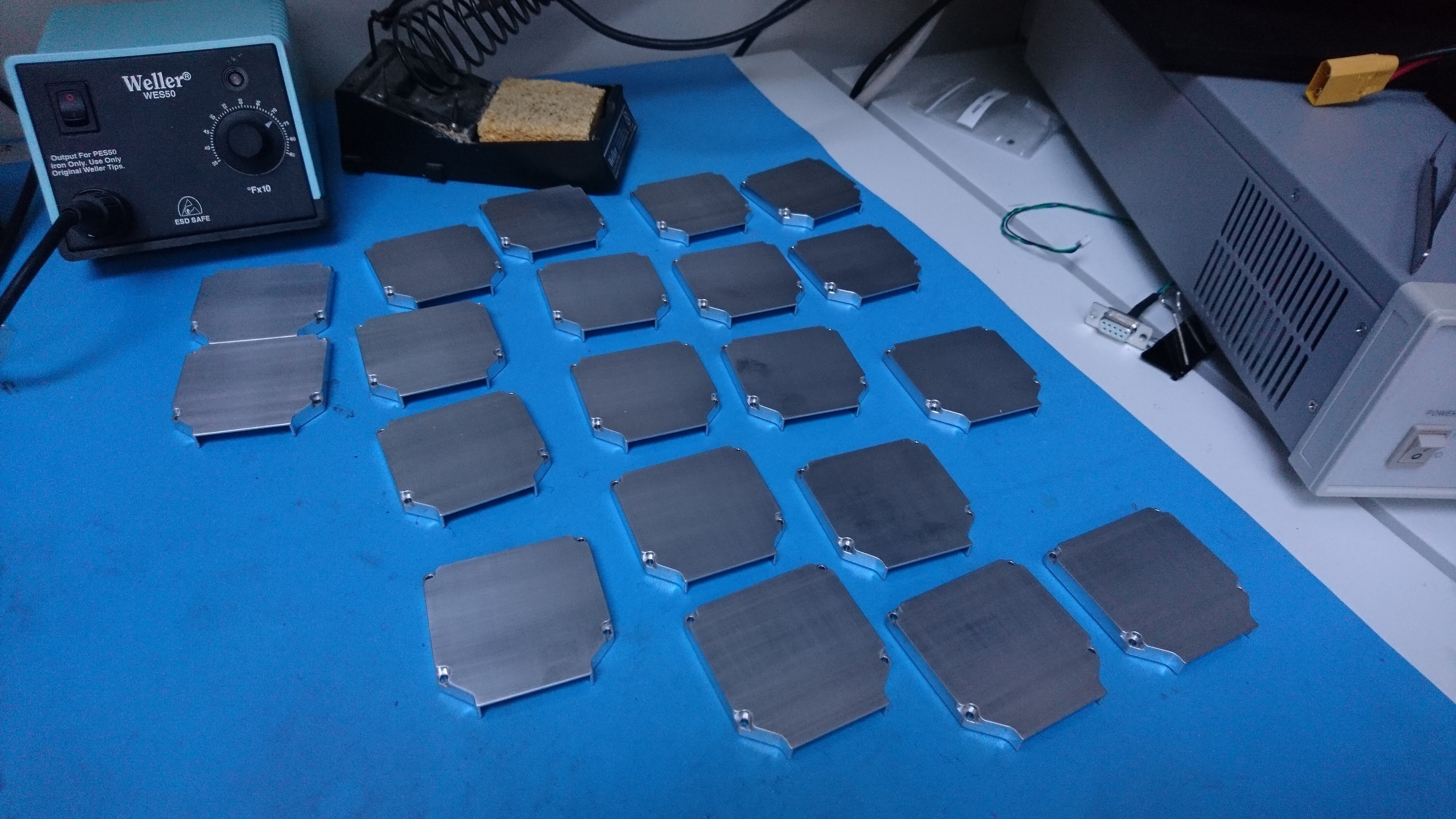

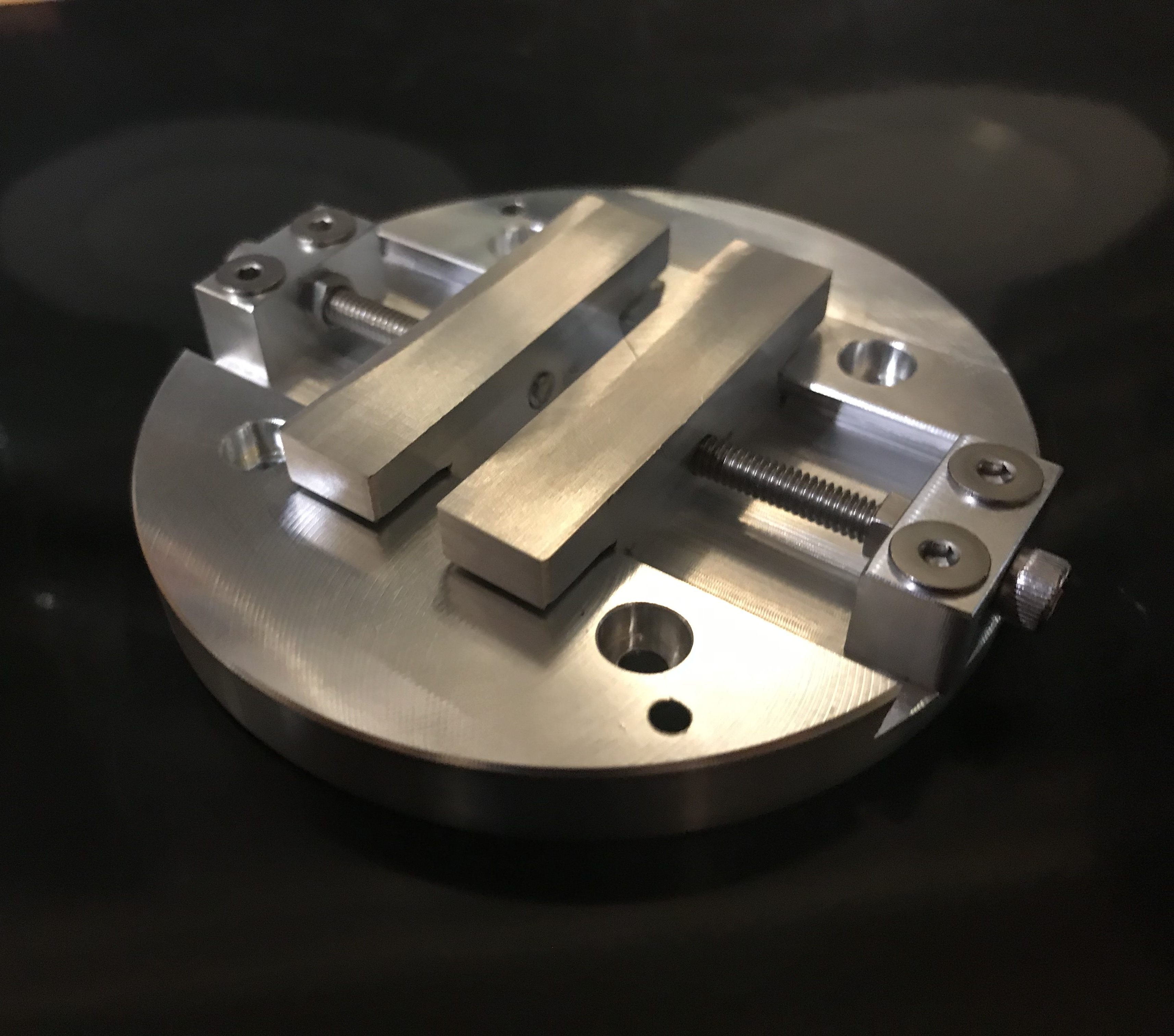

After building up the first set of qdd100 servos, I wanted to empirically measure their performance parameters. Some astute commenters uncovered in my terrible juggling video, that I didn’t actually have any ground truth measure of torque with these actuators. Given that the ultimate torque is a pretty useful performance metric, it’s a good thing to have a solid understanding of.