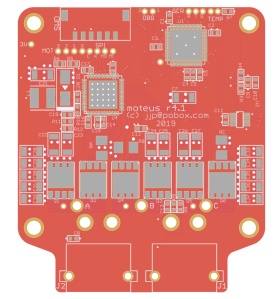

Endurance testing moteus controller r4.1

Before ordering a bigger batch of the new moteus r4.1 controller, I wanted some assurance that it would be able to run for an extended periods of time under representative loads while not breaking or having thermal issues.

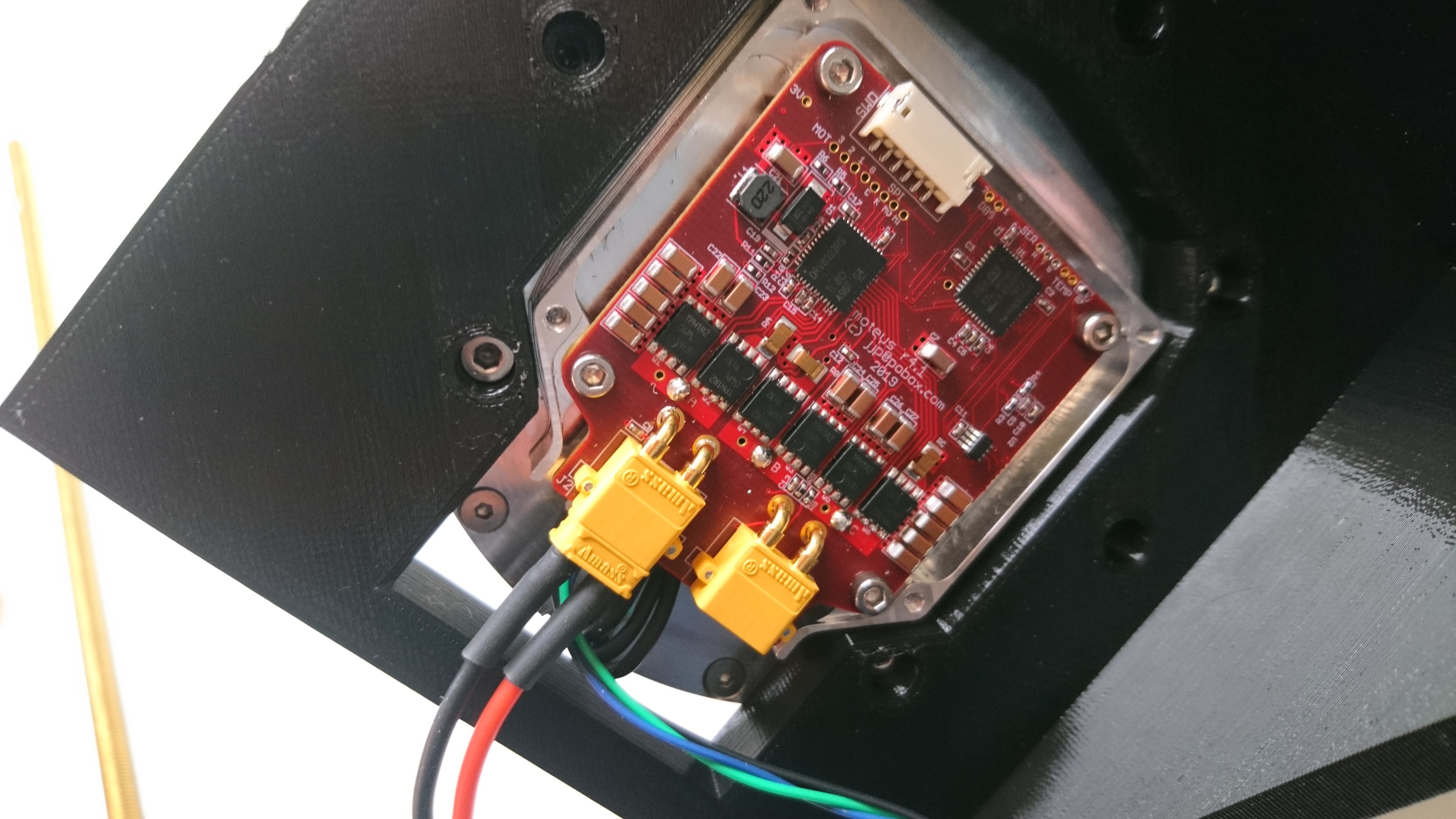

r4.1 mounted up

When I did this for the r3.1 controller, I had 2 motor joints and a planar leg built and did a jumping endurance test. I could have done that now, but building up a leg fixture was more work than I wanted to mess with at the moment, so I went with a simpler approach: