Another foot failure

The first feet I built for the quad A0 lasted for maybe an hour of walking before snapping off. The current design, has been much more robust - completing a lot of intensive walking and jumping. However, all things must fail:

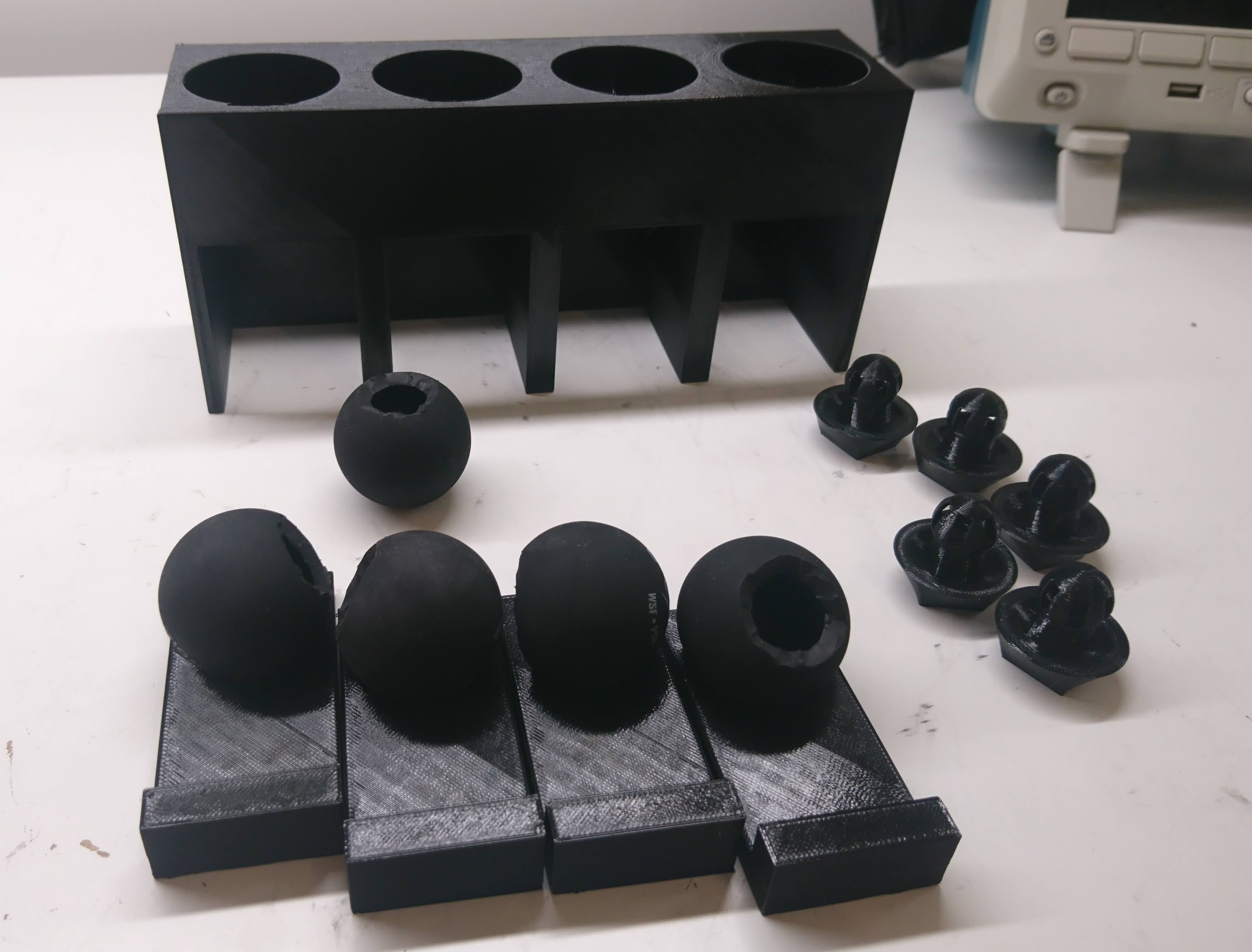

Looking at the failure, I was surprised I used so little material in the region in question. For now, I just made it 4x thicker and we’ll see how long that lasts, although ultimately it may need to be a different design or machined instead of 3d printed.