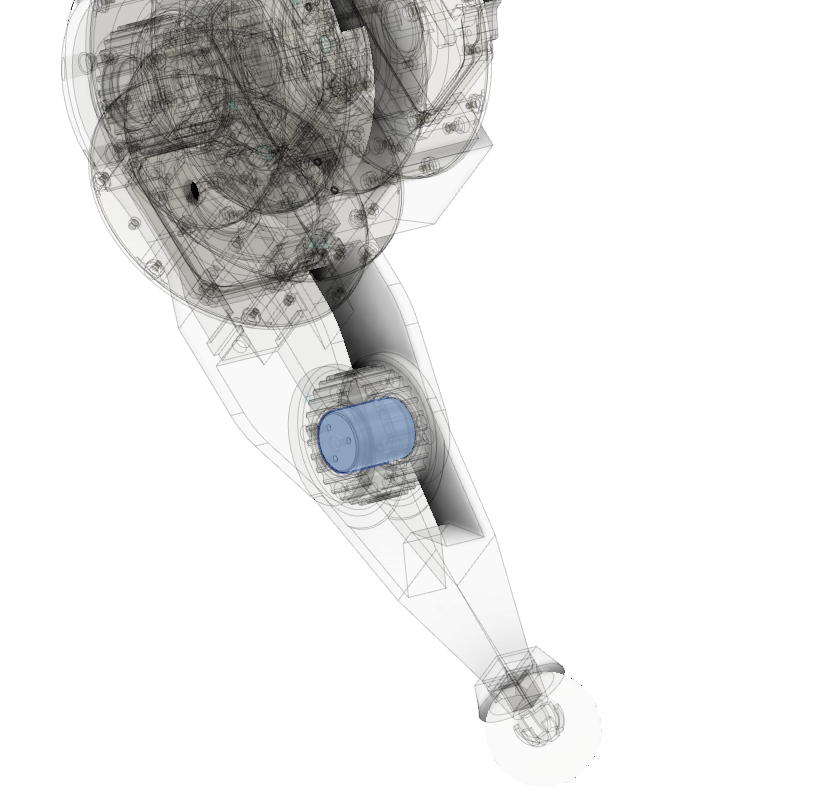

mk2 leg knee stud

One of the parts on the original quad A0’s leg that was prone to failure was the “knee stud”, a little cylinder that acted as the mating interface between the upper leg and the lower leg. It directly attaches to the upper leg, and has bearings that ride between it and the lower leg. The entire tension of the leg belt is born in shear by this part.

In the mk1 leg, this part was 3d printed with heat set inserts used to form the threaded holes. This mostly worked, although occasionally the stud could shear along the 3d printed lamination lines. Thus, for the mk2 leg, I’m making this part out of 6061.