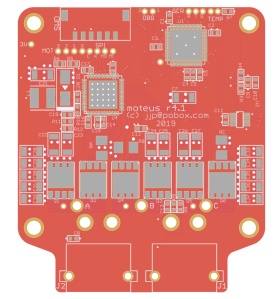

moteus controller r4.1

Another step in my plan for the next revision of the moteus servo mk2, is an updated controller board. As mentioned in my roadmap, I wanted to revise this board to make improvements in a number of domains:

- Communications: Now instead of RS485, the primary communications interface is FD-CAN. This supports data rates of up to 8 Mbit and packet lengths up to 64 bytes. The header is nominally at the original CAN bit rate, but I have no need to be standards compliant and am running very short busses so I may run everything at the higher rate.

- Connectors: Now there exist power connectors, in the form of XT30 right angle connectors and they are also daisy chainable like the data connectors. Additionally, all the connectors exit from the bottom of the board to make routing easier in configurations like the full rotation leg.

- Controller: This uses the relatively new STM32G4 controller series. It is lower power than the STM32F4, supports FD-CAN, and also supports closely coupled memory, which may allow me to improve the speed of the primary control loop execution by 3 times.

- Voltage range: This board now has 40V main FETS, with all other components at 50V rating or higher. Thus it should be safe with inputs up to 8S (34V or so).

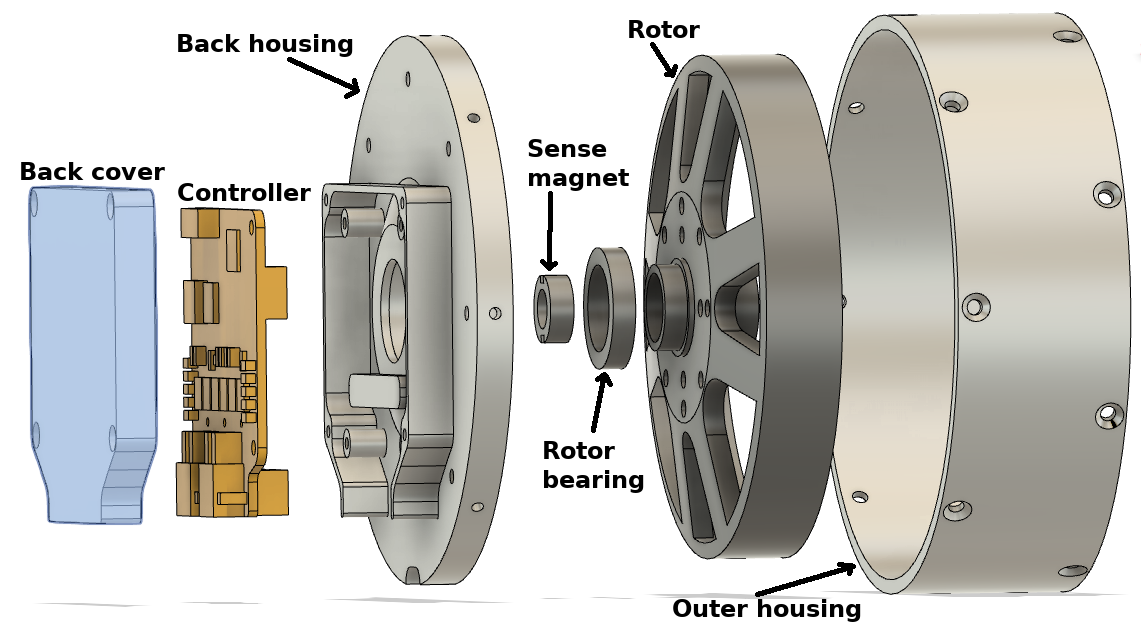

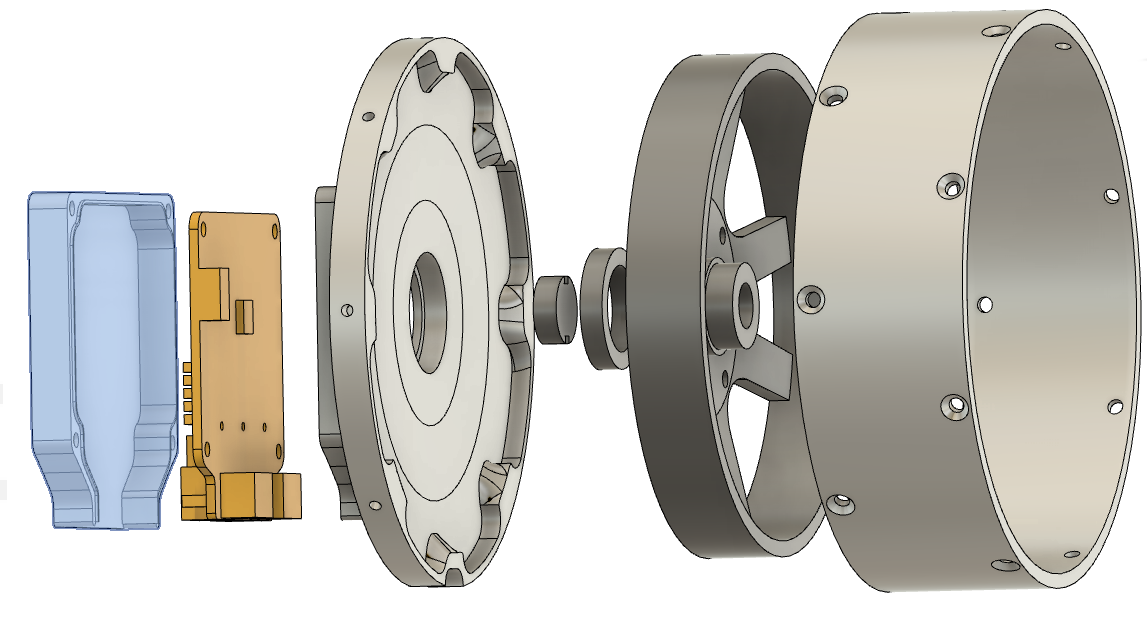

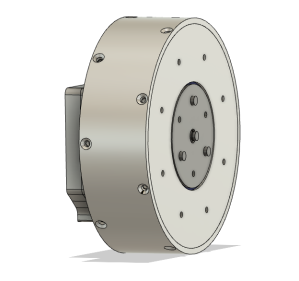

moteus r4.1 rendering