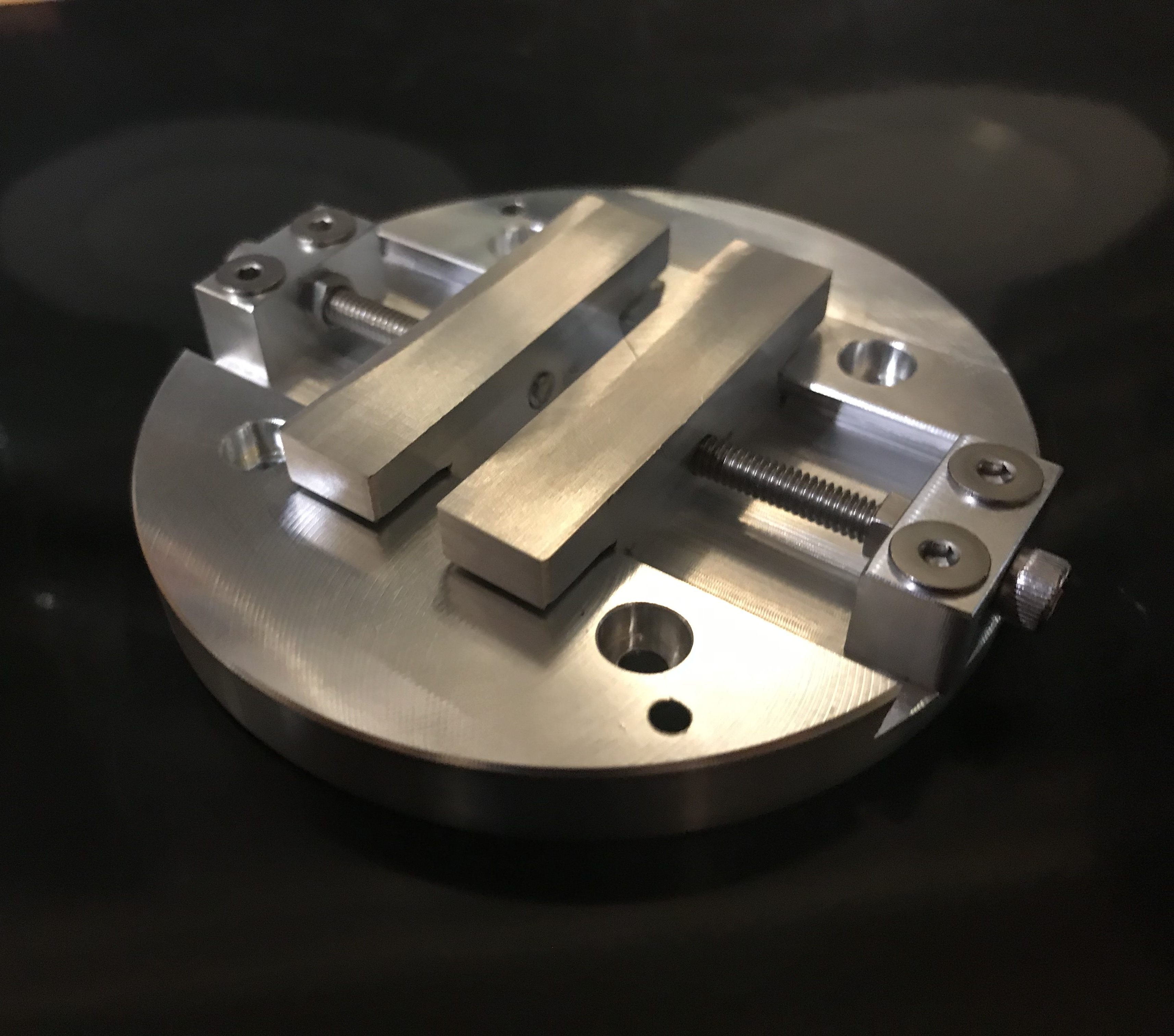

New quad power distribution board

Finally returning back to other pieces of my quad roadmap, I finished getting an updated power distribution board ready for the quad A0. This board is one I had made many months ago and mostly brought up, but then didn’t quite finish. The r1 was when I first discovered my unfortunate stm32g4 pinout problems that doomed 3 of my in flight boards. The pictures here are of r2, which suffered from yet more pinout problems, resulting in more than my usual number of blue wires. Fortunately, identifying those problems here let me fix them ahead of time for the fdcanusb and moteus r4 boards.