First soft-jaws for CNC machining

While working to build the reduced weight moteus servo mk2, I got tired of hand machining the first operation on a manual mill and lathe for the front and back housings. It was necessary, primarily to enable workholding on the PocketNC v2-50, but also because it allowed me to remove much of the excess material more quickly than could be done on the PNC. So, I got trained up on the AA CNC Bridgeport and went to town.

The manual work I did on the mill used V blocks to hold the round stock, but for this I wanted something that was more repeatable and would offer more gripping power. Thus I decided to try my hand at soft jaws for the first time. I got some blanks from MonsterJaws which would fit the vise there and got started.

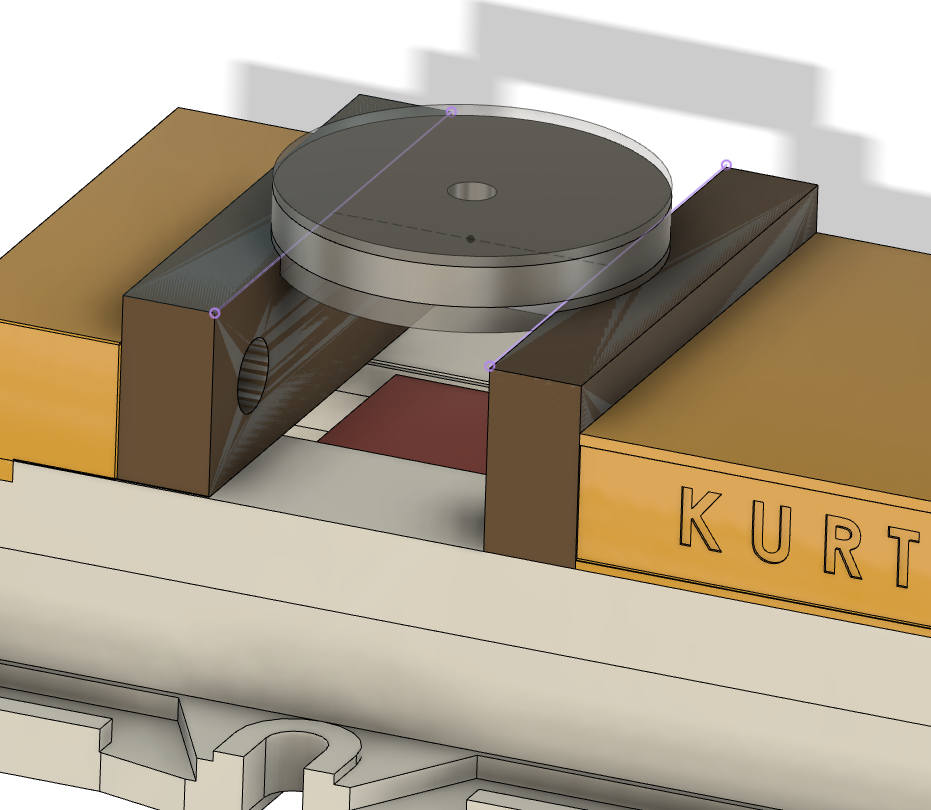

For the CAD/CAM, I grabbed a random 6" Kurt vise model from the interwebs and stuck my part in it. Then I added the vise blanks and used a “combine” operation to subtract out the stock from the blanks.

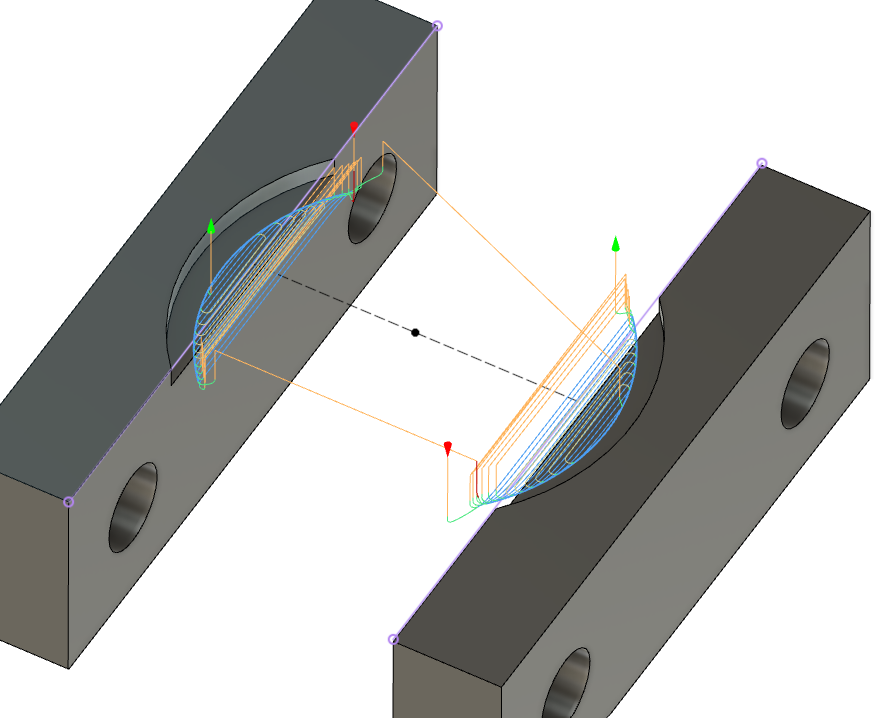

Then, when doing the CAM, I just ran a 3d adaptive followed by a finishing contour pass:

When I ran the actual toolpath, I messed up and had the spindle running about 1/3 of the speed I wanted, which made for some nice chomping noises, but it did cut.

Blanks ready to cut

Stock mounted!