Quadruped Junction Board

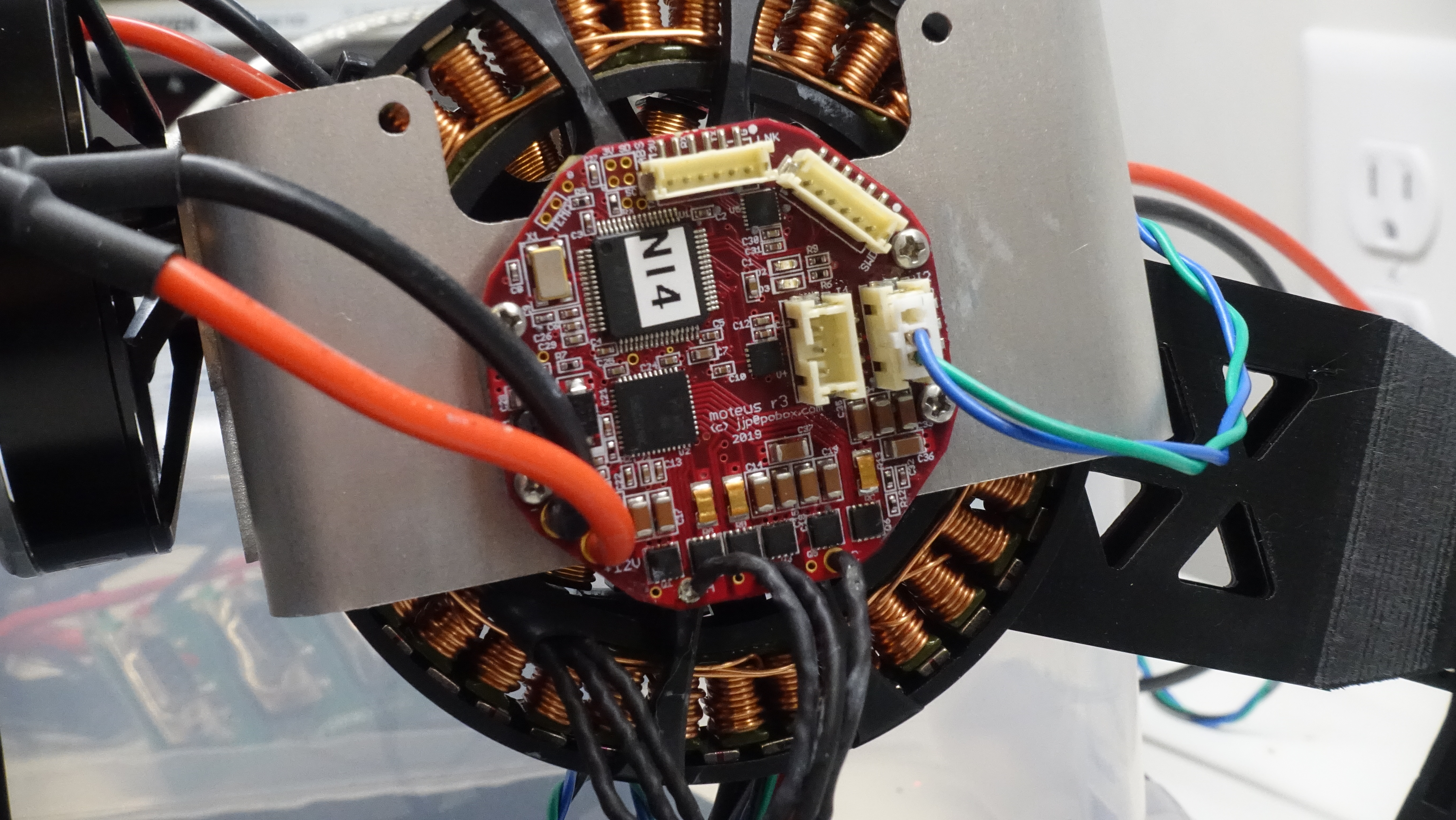

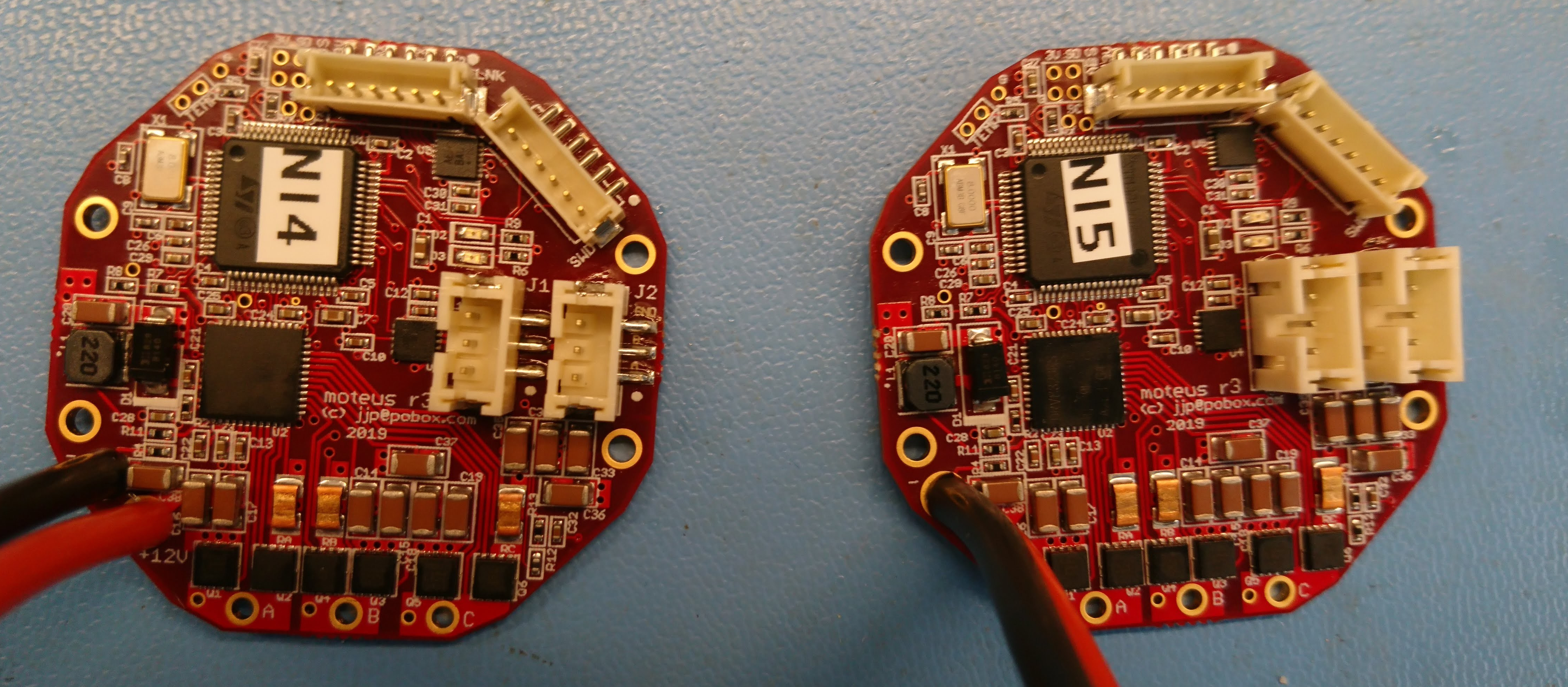

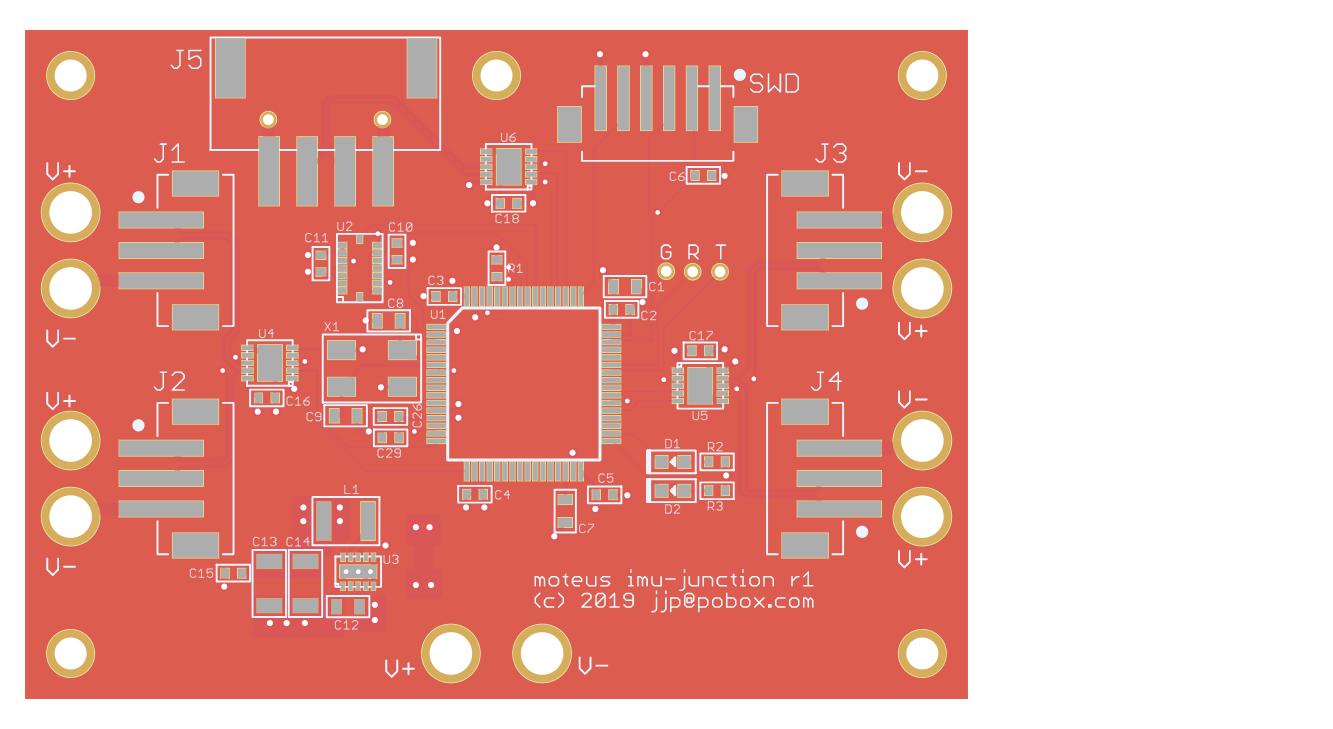

The full quadruped robot needs to both distribute power from the primary battery and RS485 serial network to all 12 servos. To make the wiring of that easier, I’ve made up a junction board to provide power connectors, distribute the data network, and act as the IMU for when that is necessary.

The RS485 network is bridged between two halves of the robot. One connection comes in from the controlling PC and two separate links go out, one for the left side and one for the right side. This could eventually allow the controller on the junction board to take intelligent actions itself, such as querying the force applied on all 12 servos. It could then return the result in a single RS485 transaction to the host computer. I am expecting that will be necessary to achieve closed loop control approaching 1kHz.