Encoder autocalibration

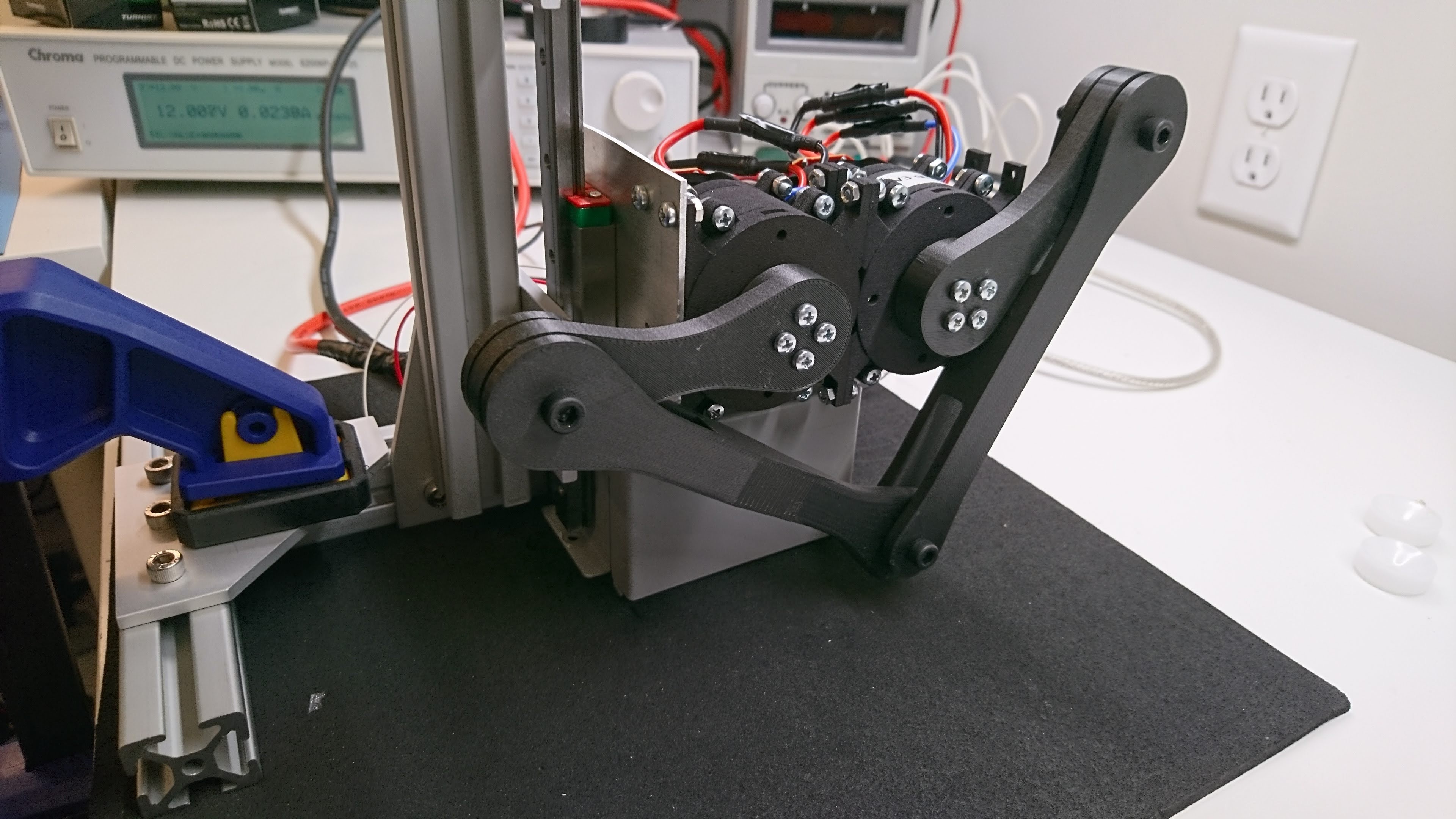

I have been continuing to iterate on the control and mechanical aspects of the improved actuators for SMMB. While working on an alternate board mounting strategy, I ended up with a magnet that was much much further from the absolute encoder than before. This resulted in significant errors in the estimated motor phase at various points in the revolution of the absolute encoder. In the spirit of copying every single thing Ben Katz did in his project, I implemented a piecewise linear encoder calibration technique.