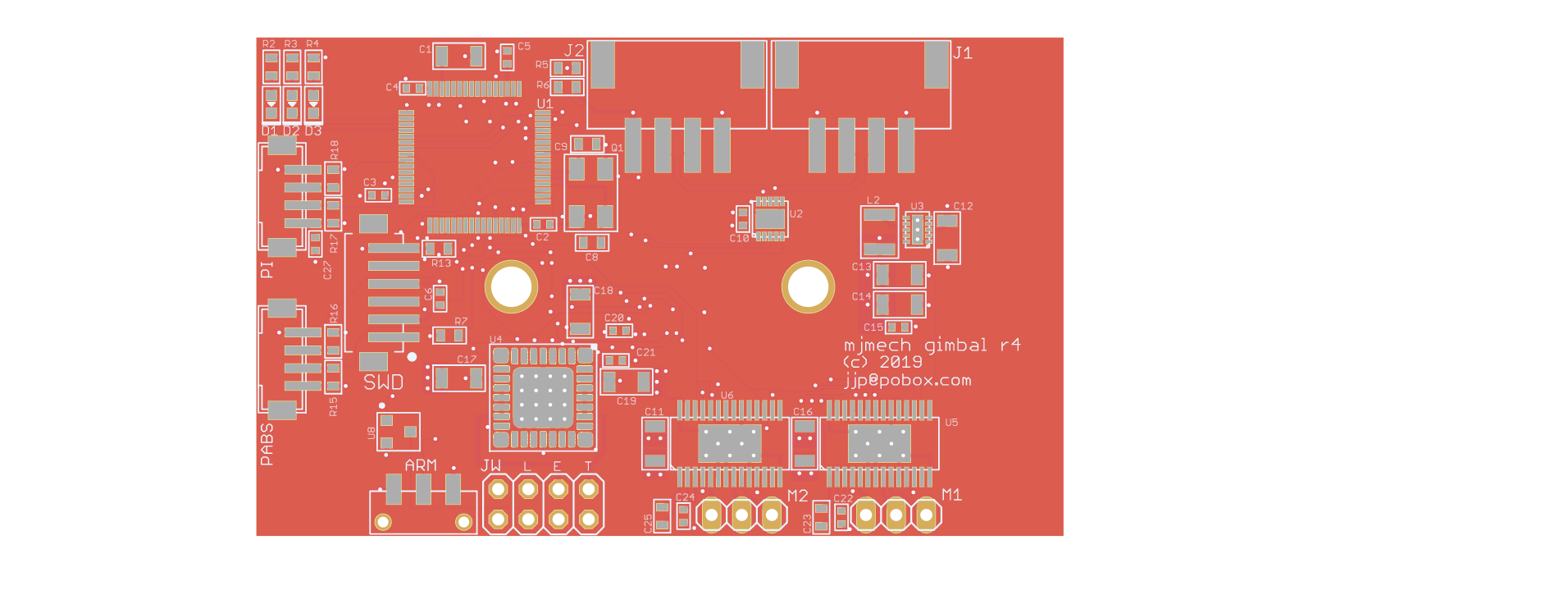

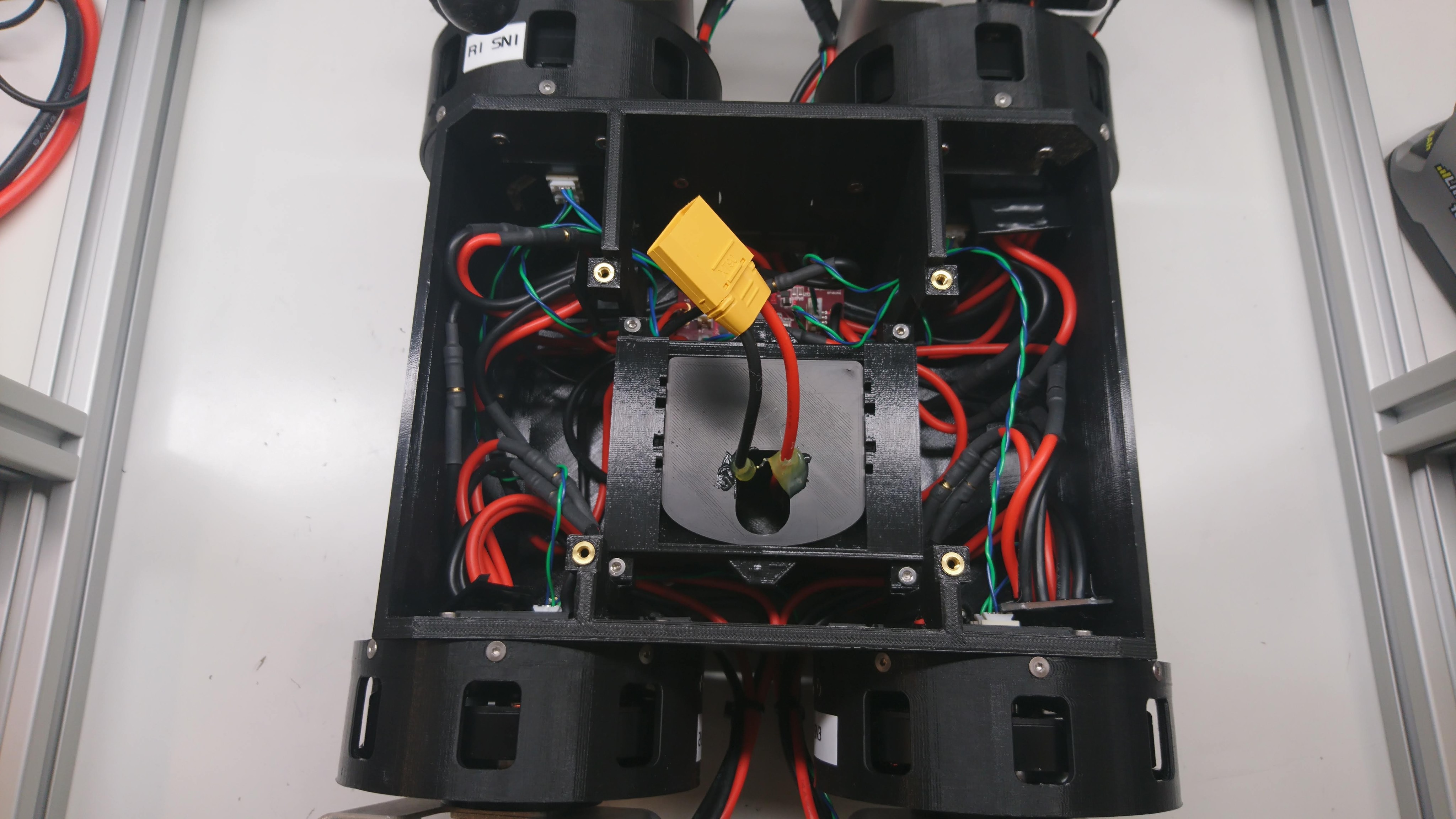

pre-charge circuit

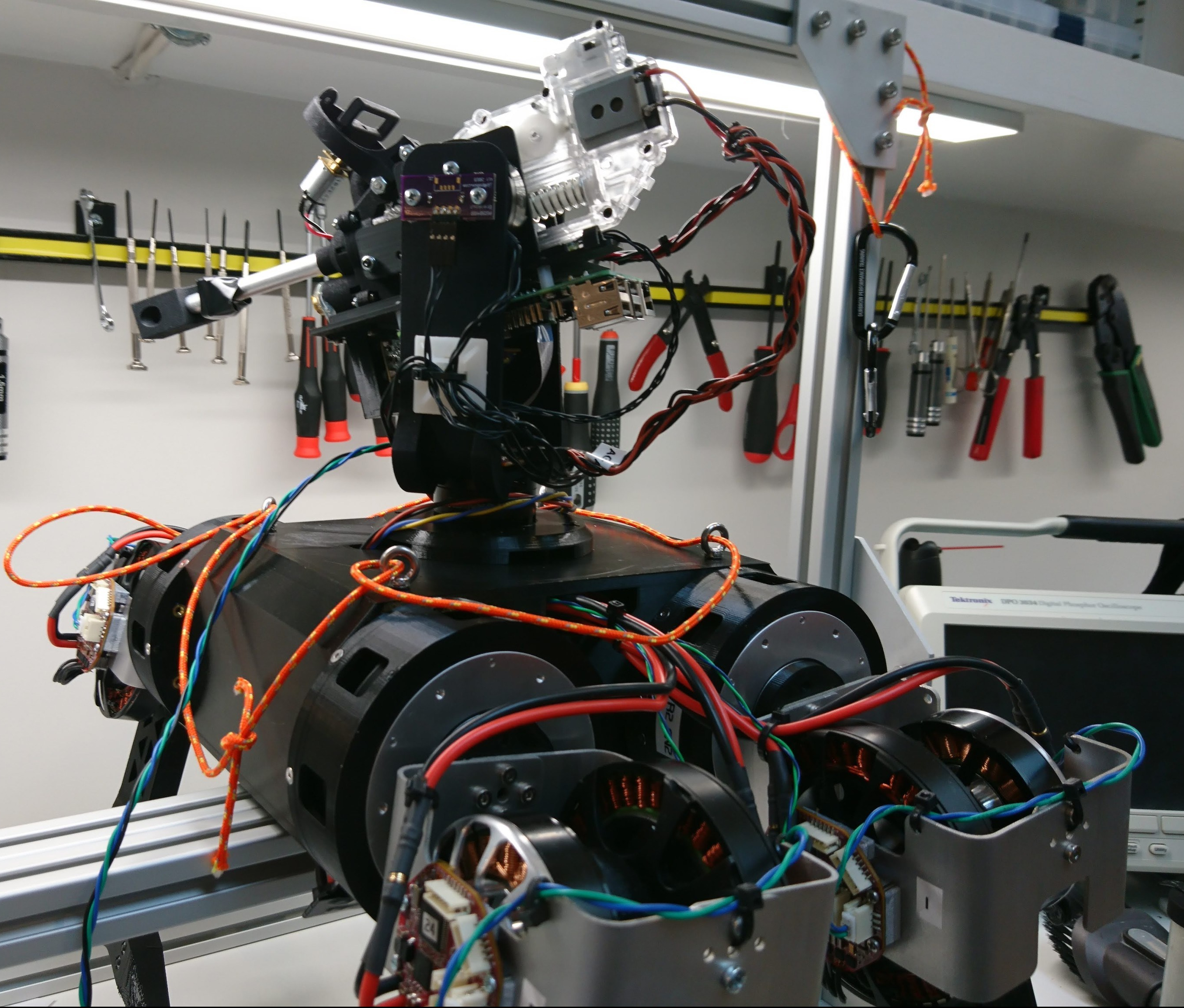

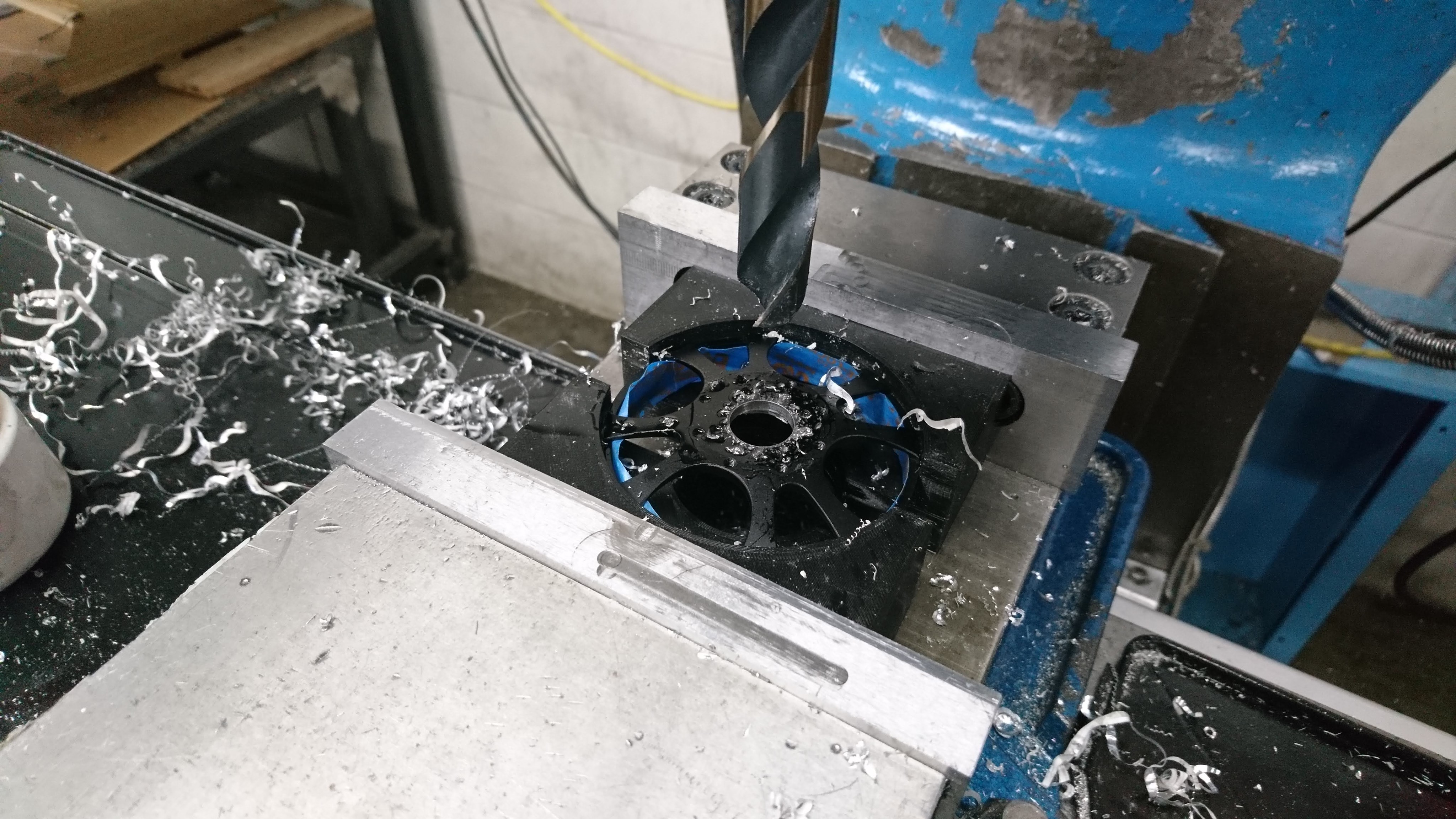

Next up in Super Mega Microbot 2’s existence is being able to run untethered. Before that can happen, I need to be able to plug in a battery, and hopefully not have everything explode. As seen with the IMU junction board, even minor inductive links can result in chips getting toasted. I had thought that just adding sufficient capacitance to each of the point-of-load converters would resolve the issue, but in fact that almost made it worse.