Measuring the pi3hat r4.2 performance

Last time I covered the new software library that I wrote to help use all the features of the pi3hat, in an efficient manner. This time, I’ll cover how I measured the performance of the result, and talk about how it can be integrated into a robotic control system.

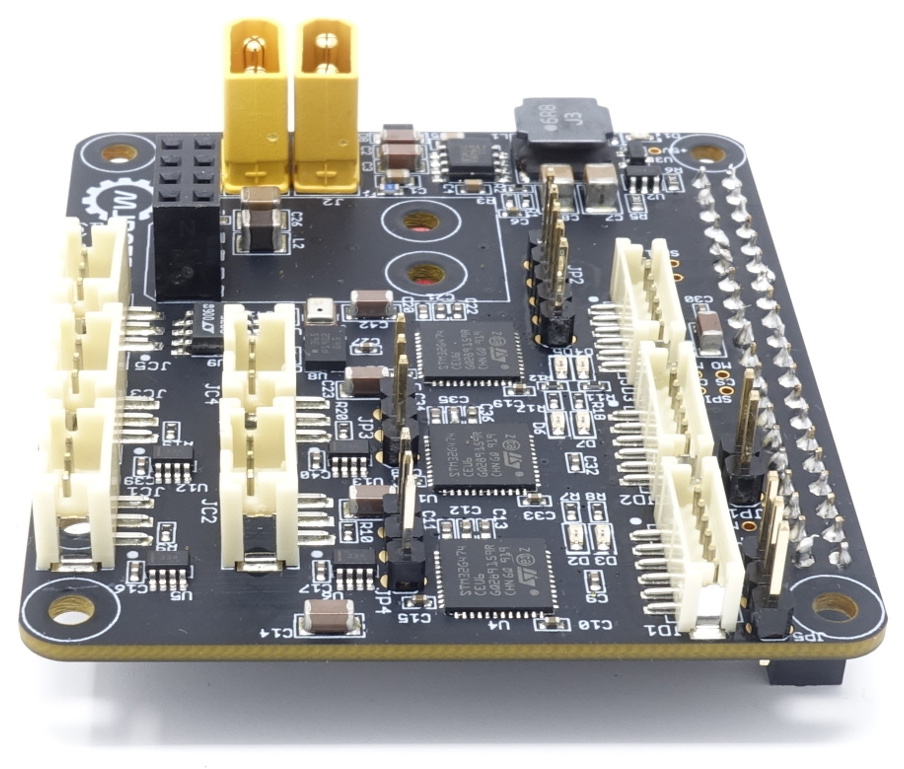

pi3hat r4.2 available at mjbots.com

Test Setup

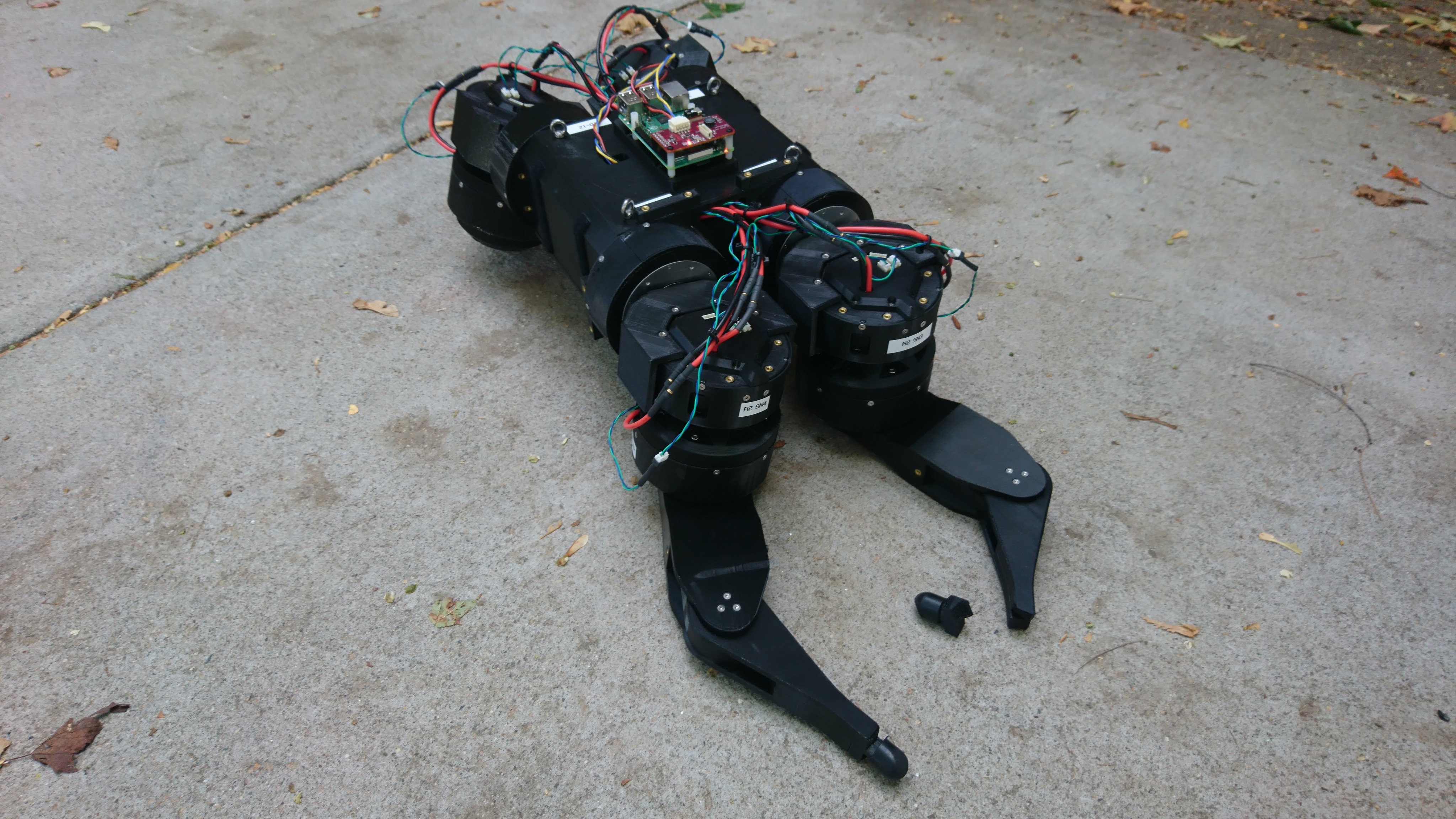

To check out the timing, I wired up a pi3hat into the quad A1 and used the oscilloscope to probe one of the SPI clocks and CAN bus 1 and 3.