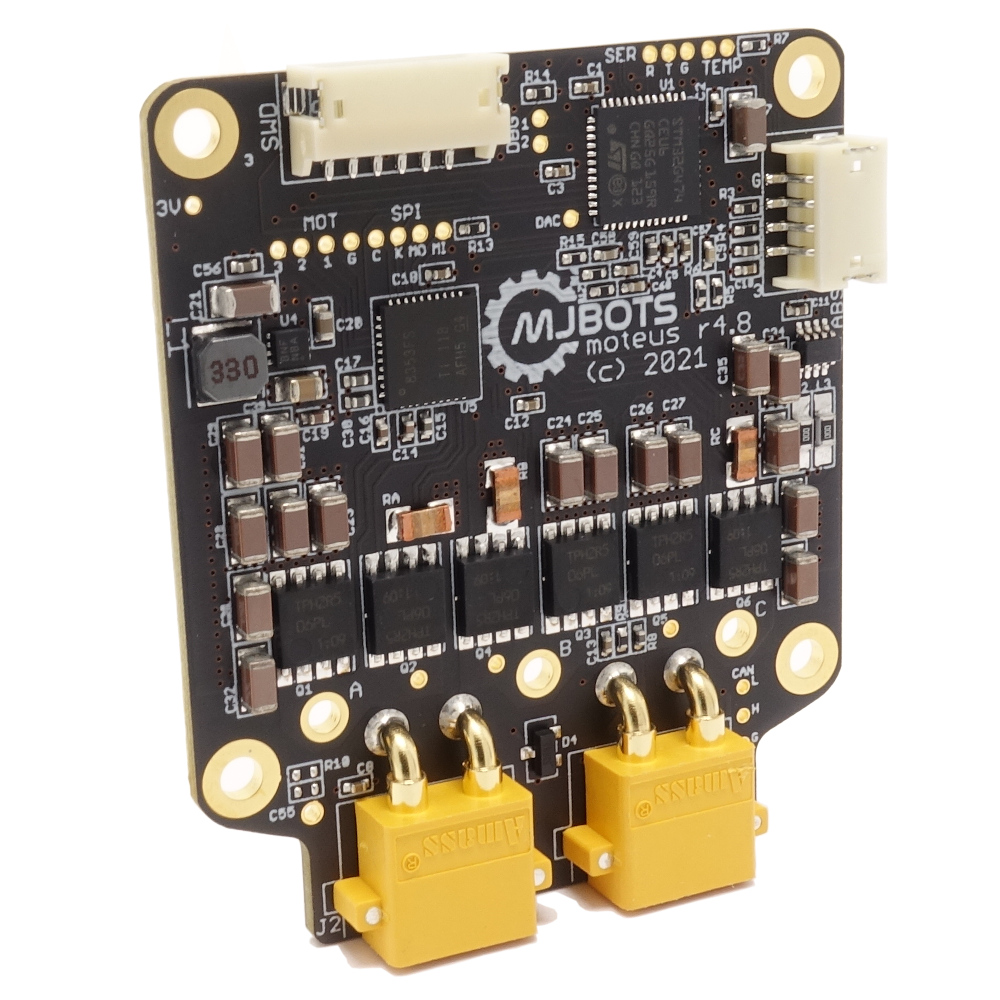

Velocity and acceleration limited trajectories

One of the oldest requested features for the moteus brushless controller has been a form of trajectory control beyond constant velocity trajectories. For most applications this is not an actual deal-breaker, because arbitrary trajectories can be approximated by piecewise linear constant velocity trajectories in the application layer. However, for many people, that is big hurdle to jump over to start with, and for some, it can actually limit application effectiveness because a fair amount of CAN bandwidth is required to achieve the high rate control necessary for smooth motion.