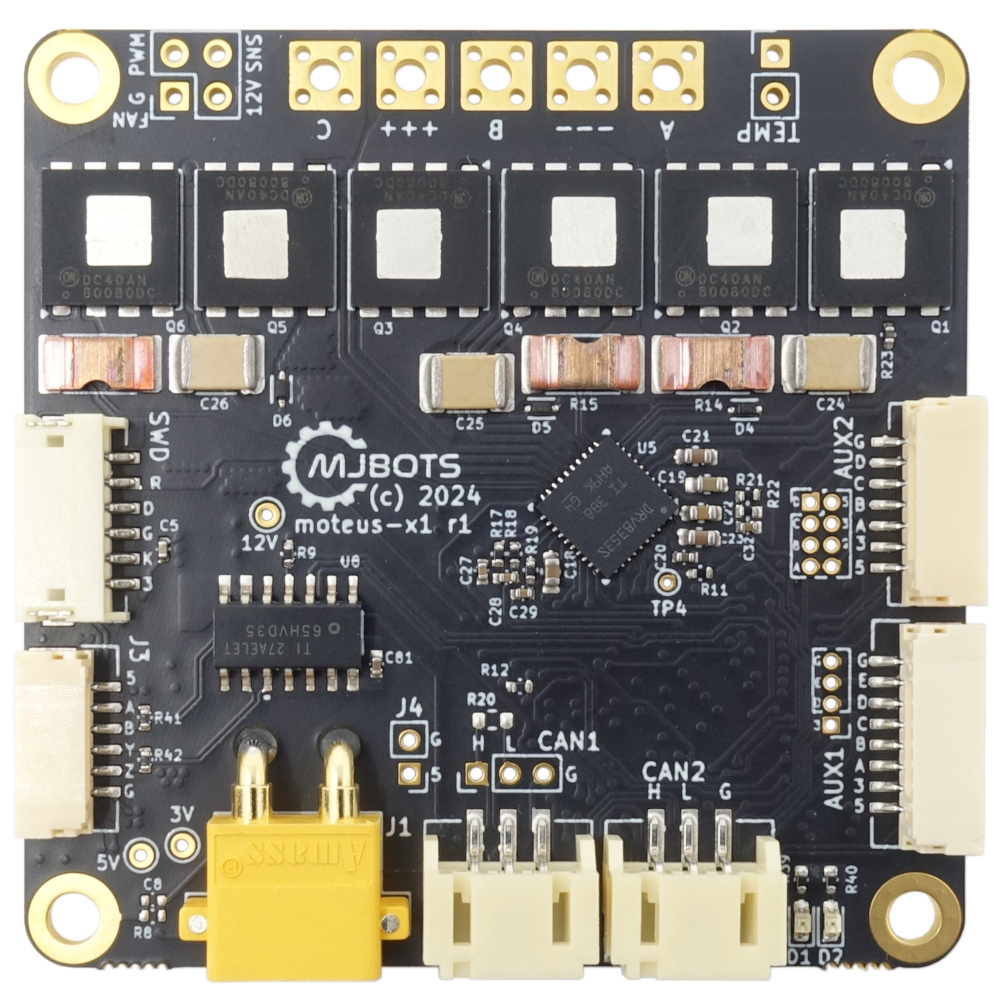

moteus-x1

I’m excited to announce the release of the newest moteus motor controller, the moteus-x1!

The biggest differences between the moteus-x1 and other moteus controllers is improved output phase current capacity. The x1 is rated for 25A continuous output phase current with no cooling and 60A continuous with fan based cooling. The other big improvement are 12V fan output pads with PWM support. Supporting high power cooling helps the x1 to achieve its higher output current rating.