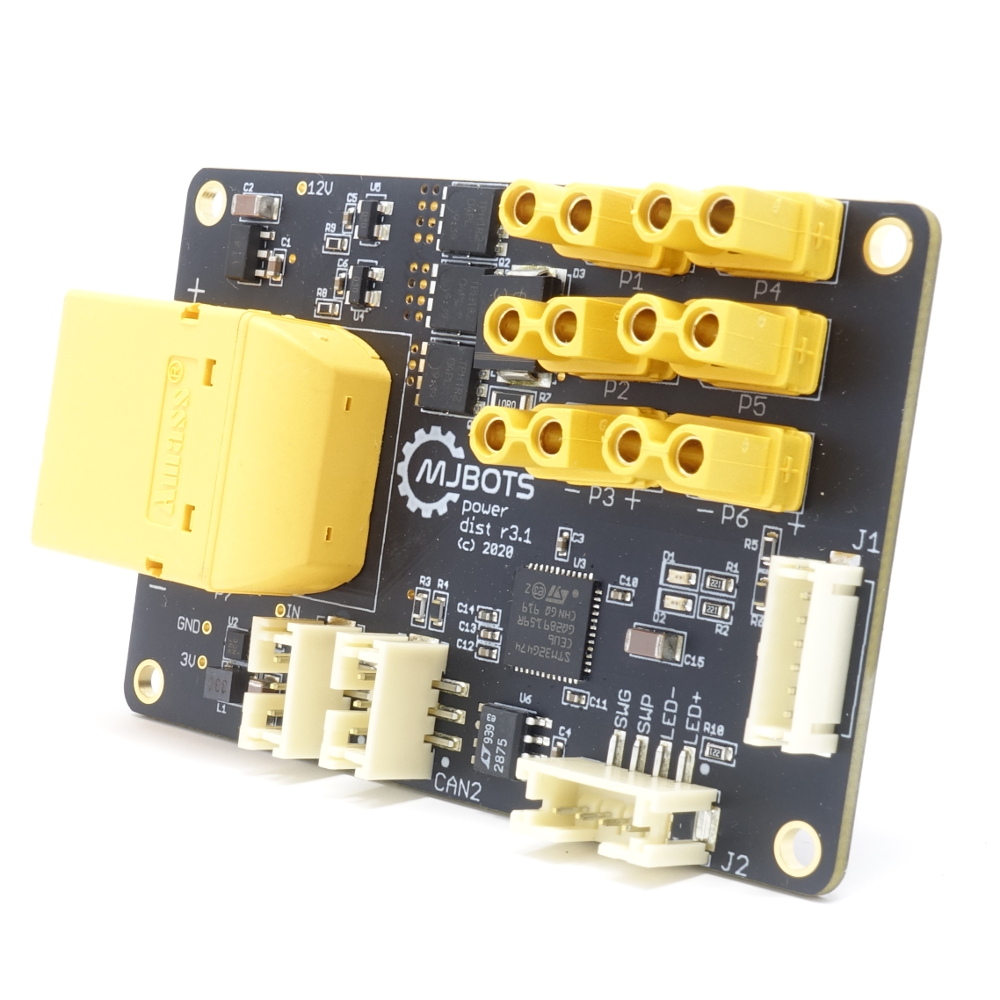

Next-gen power_dist (part 2)

Last time I covered the limitations of the power_dist r3.1, here I’ll cover some iterations of the design process.

My initial design goals for this version are based largely around improving the major limitations identified before:

- Positive side switching: By switching the positive rail, a whole class of use failures is removed, as most people expect ground to be common throughout a system.

- Increased voltage range: moteus r4.5 and the pi3hat both support 44V, so any new power_dist board should support at least that.

- Lower quiescent current: Ideally, the quiescent current would be measured in microamps, or at least at a level that it does not confuse BMS systems.

- Energy monitoring: Often in the development of the quad A1, I wanted to have a system level power and energy monitoring solution so as to identify the energy cost of various maneuvers and gaits. Tracking that at the power_dist level seems like a logical place.

- Wider load envelope: The 3.1 version had a relatively limited maximum downstream capacitance and turn-on current draw. It was enough to power on 12 moteus controllers and a small computer, but not much else.

To achieve these goals, I decided to try using what is known as a “hot swap controller”. These are integrated circuits that are intended for use in cards that plug into server backplanes. Given that any given card could potentially have a large decoupling capacitance, inserting it live into a backplane could cause arcing, and high currents that cause the overall bus voltage to drop outside of tolerable limits.