I am a big fan of MacroFab. They’ve built a PCB + assembly + more service that is transparent, high quality, and nearly completely self service. They appear to be making money, so hopefully they will stay in business for some time.

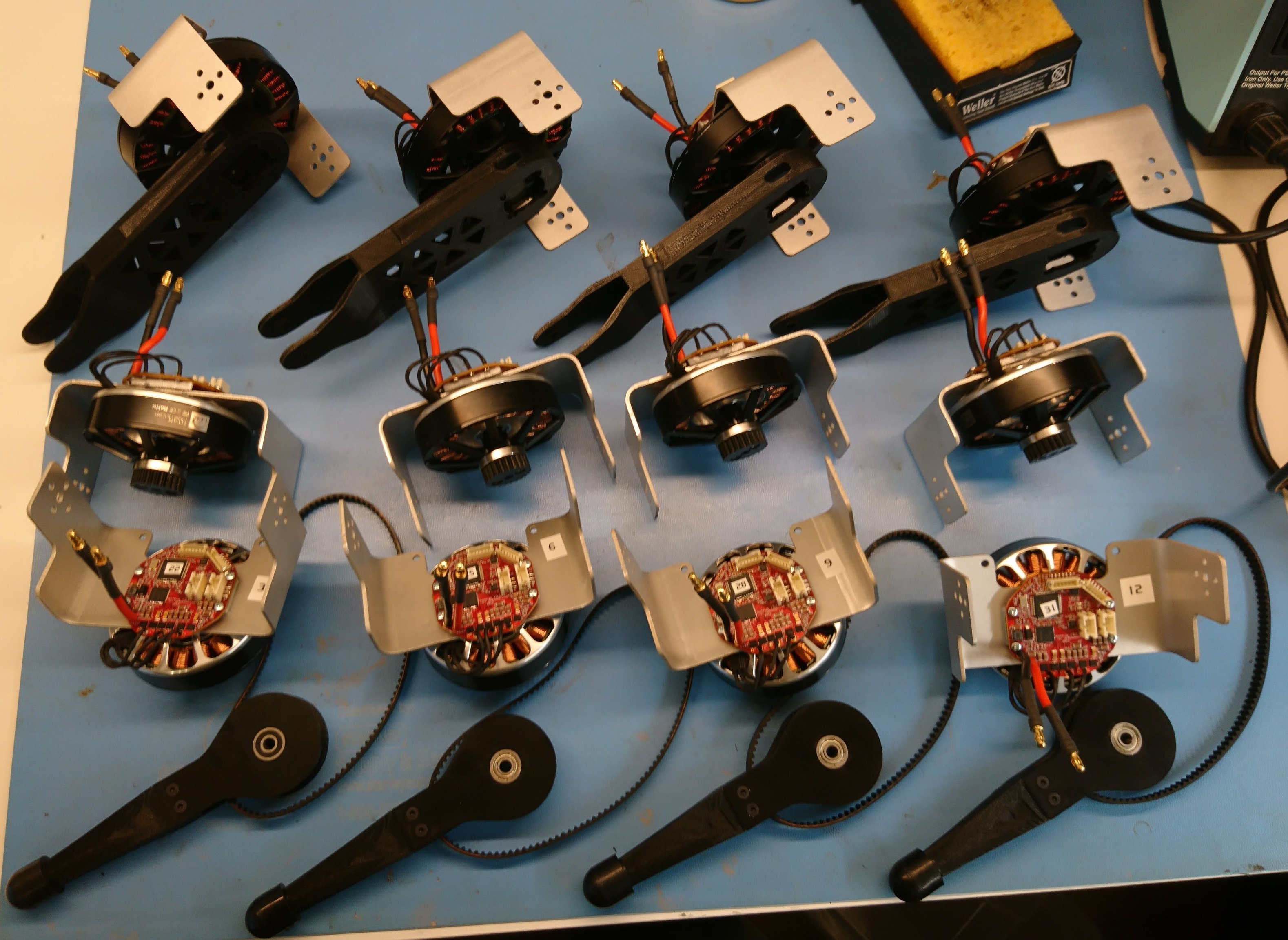

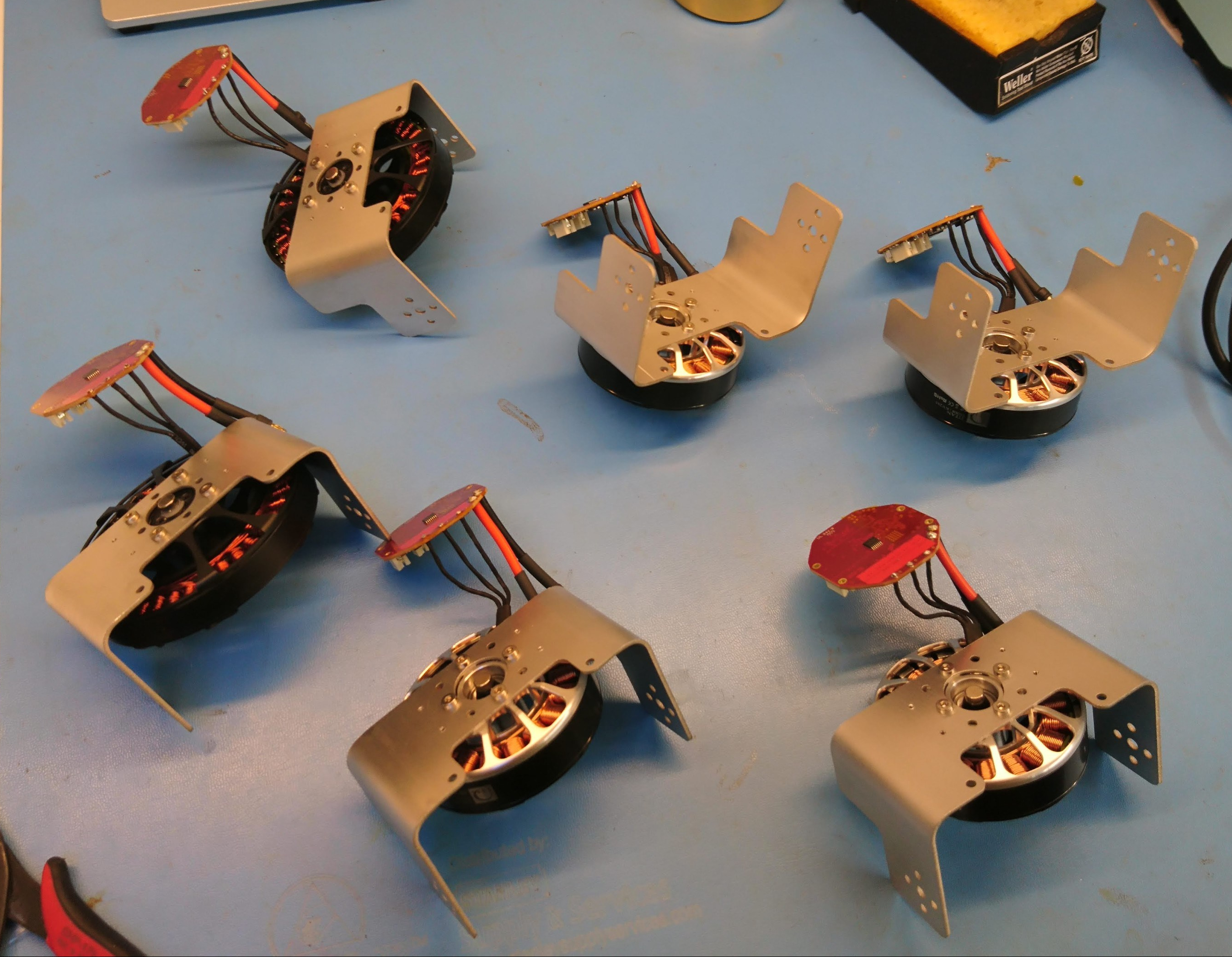

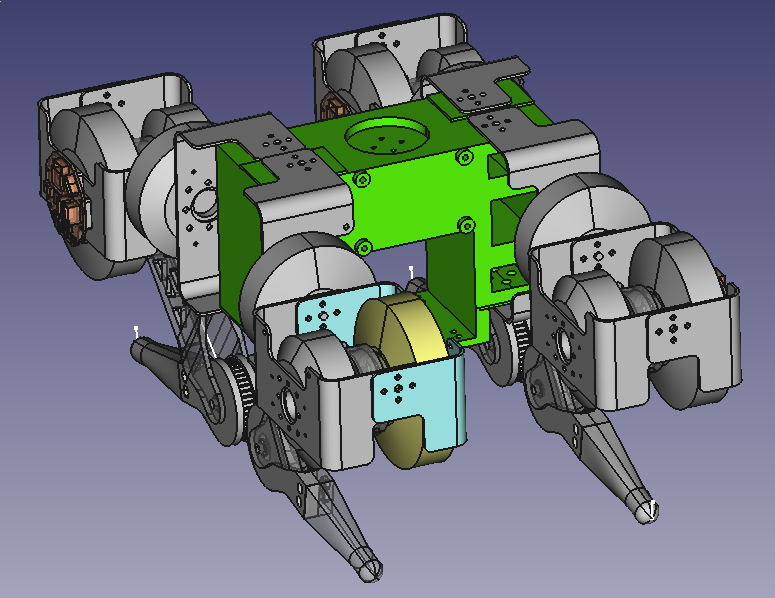

On top of that, they offer a “quick turn” option which gives you populated boards shipped 10 business days after you order them (and I’ve even had them ship out a few days early from time to time)! The only annoyance is that the quick turn option is limited, as I’ve mentioned before, to boards that meet certain criteria, among them having 20 or fewer items on the bill of materials. To try and get this first quadruped prototype up and running quickly, I’ve been exclusively relying on quick turn boards, which means making some compromises. Even after some moderate design sacrifices, I haven’t been able to get the servo controller board to 20 parts. At the moment it is 23. Thus, when I received the first big-ish PCB order I’ve made (qty 28), I got to spend a morning populating the remaining 3 components on all 28 boards.