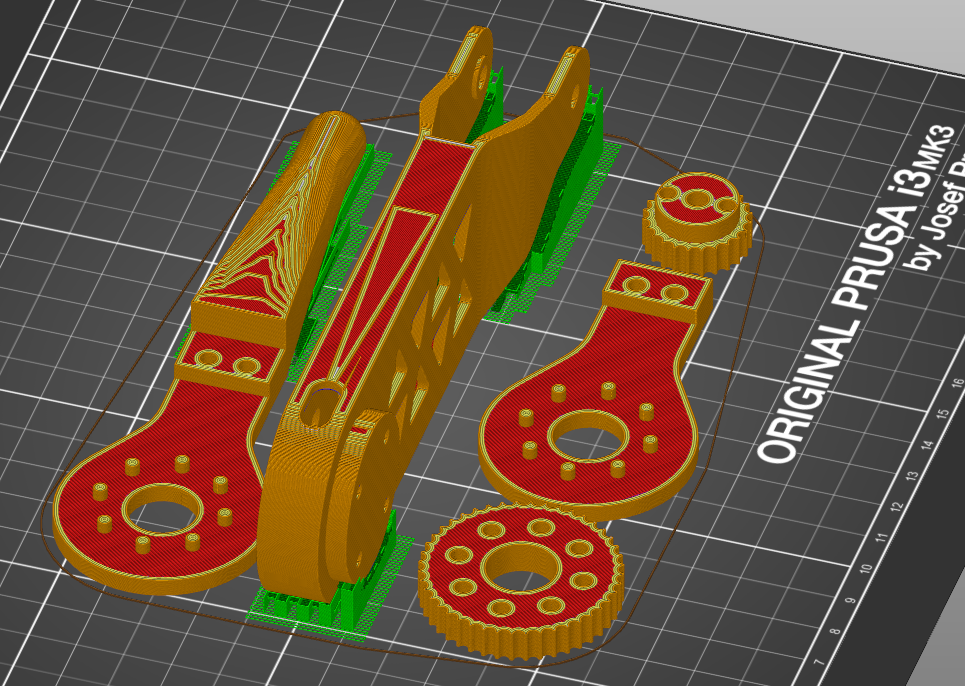

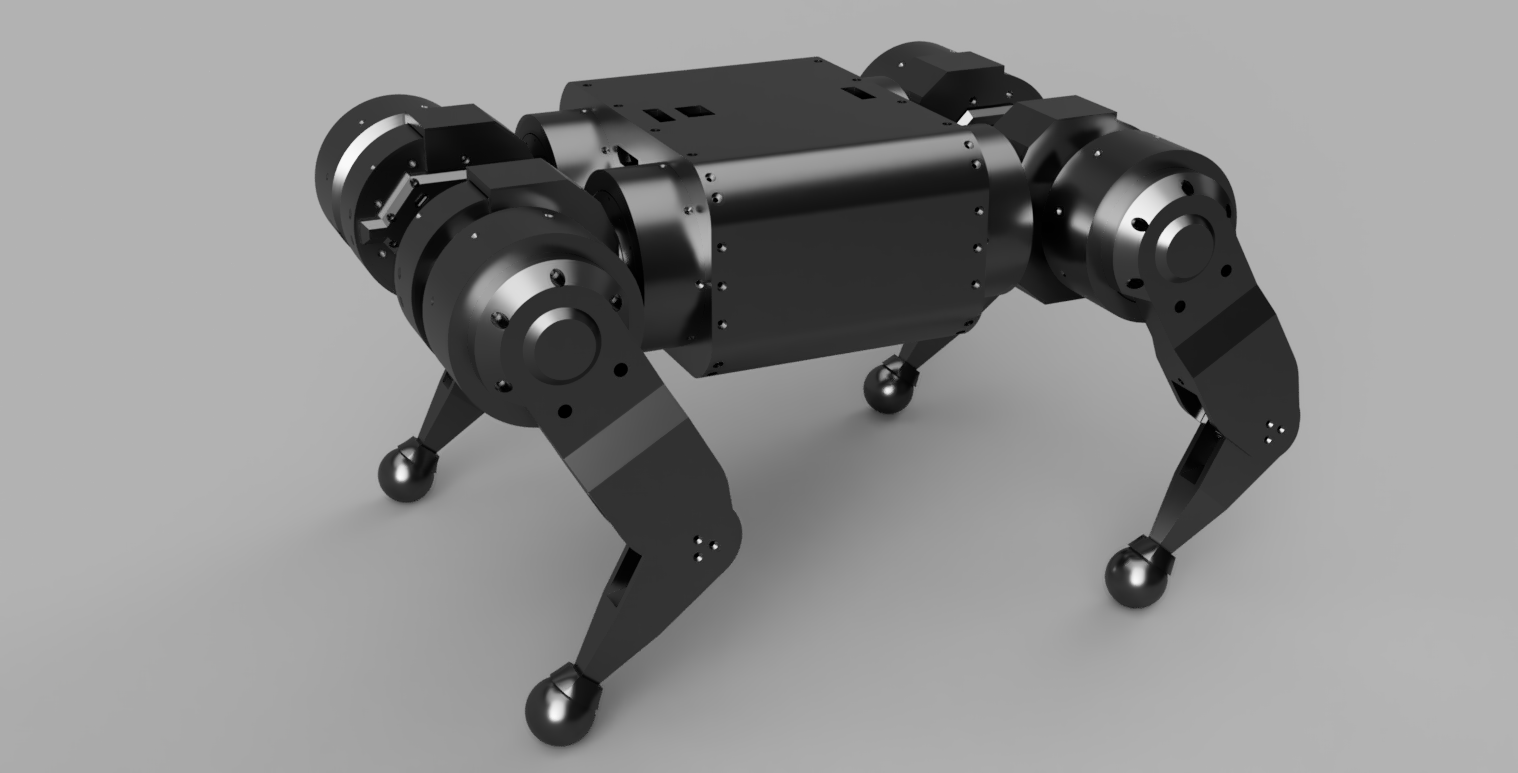

quad A0 chassis v2 - design

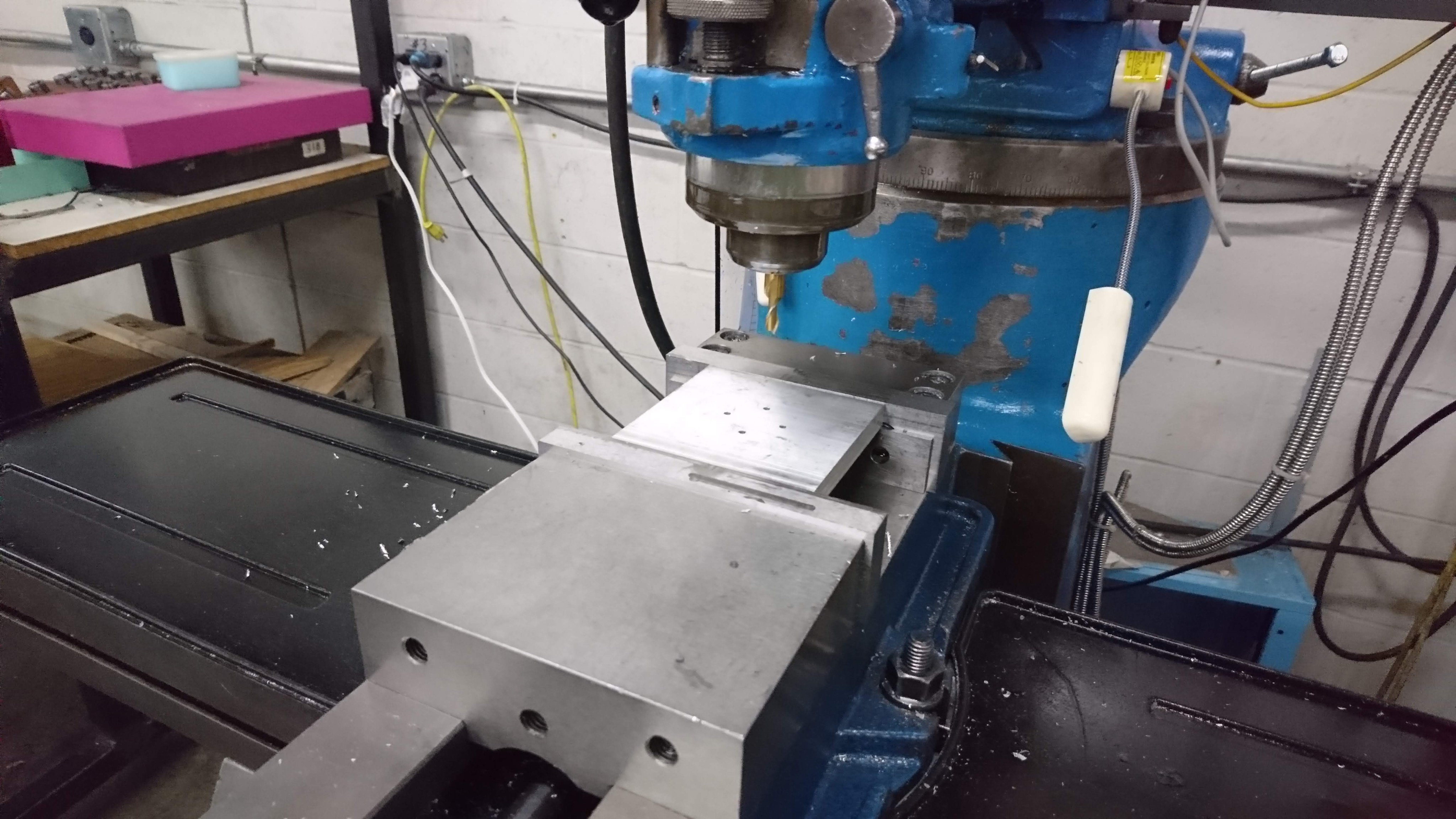

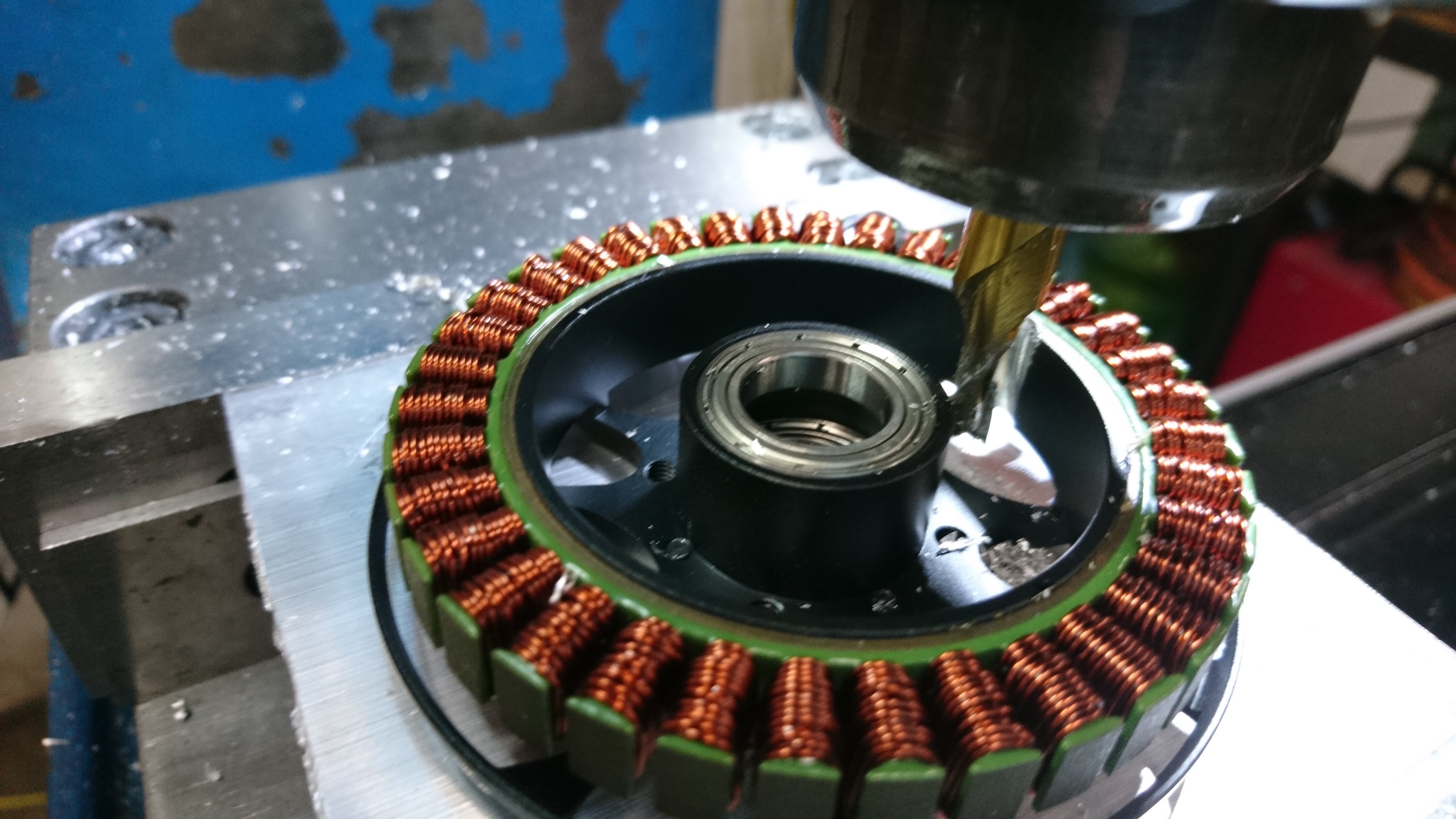

As described in my roadmap, the chassis for the quad A0 was on the verge of failing, or causing the shoulder motors themselves to fail, after only a few hours of walking around. Also, it was nigh impossible to assemble, disassemble, or change anything about it. Thus, the chassis v2!

More than one piece

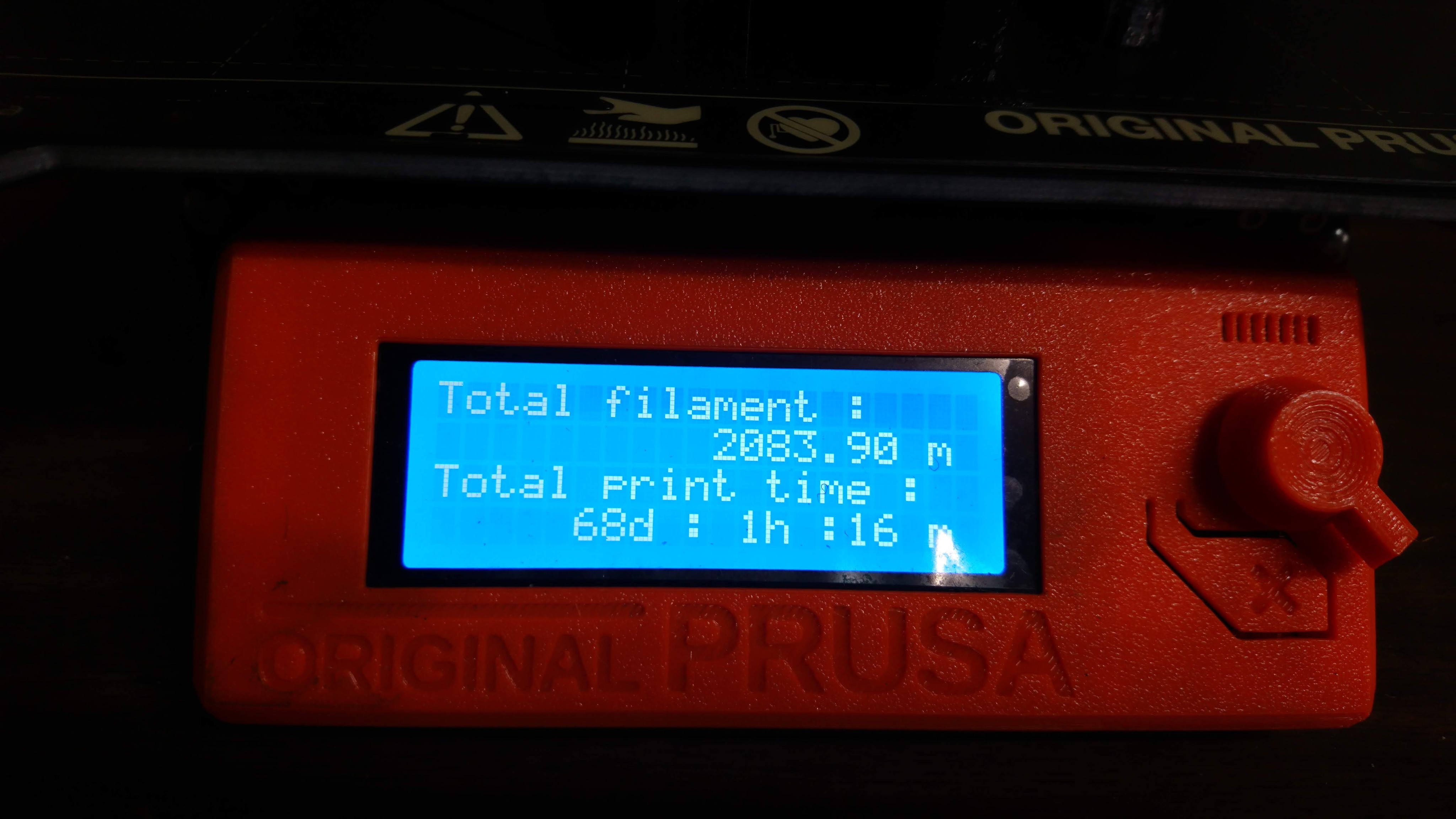

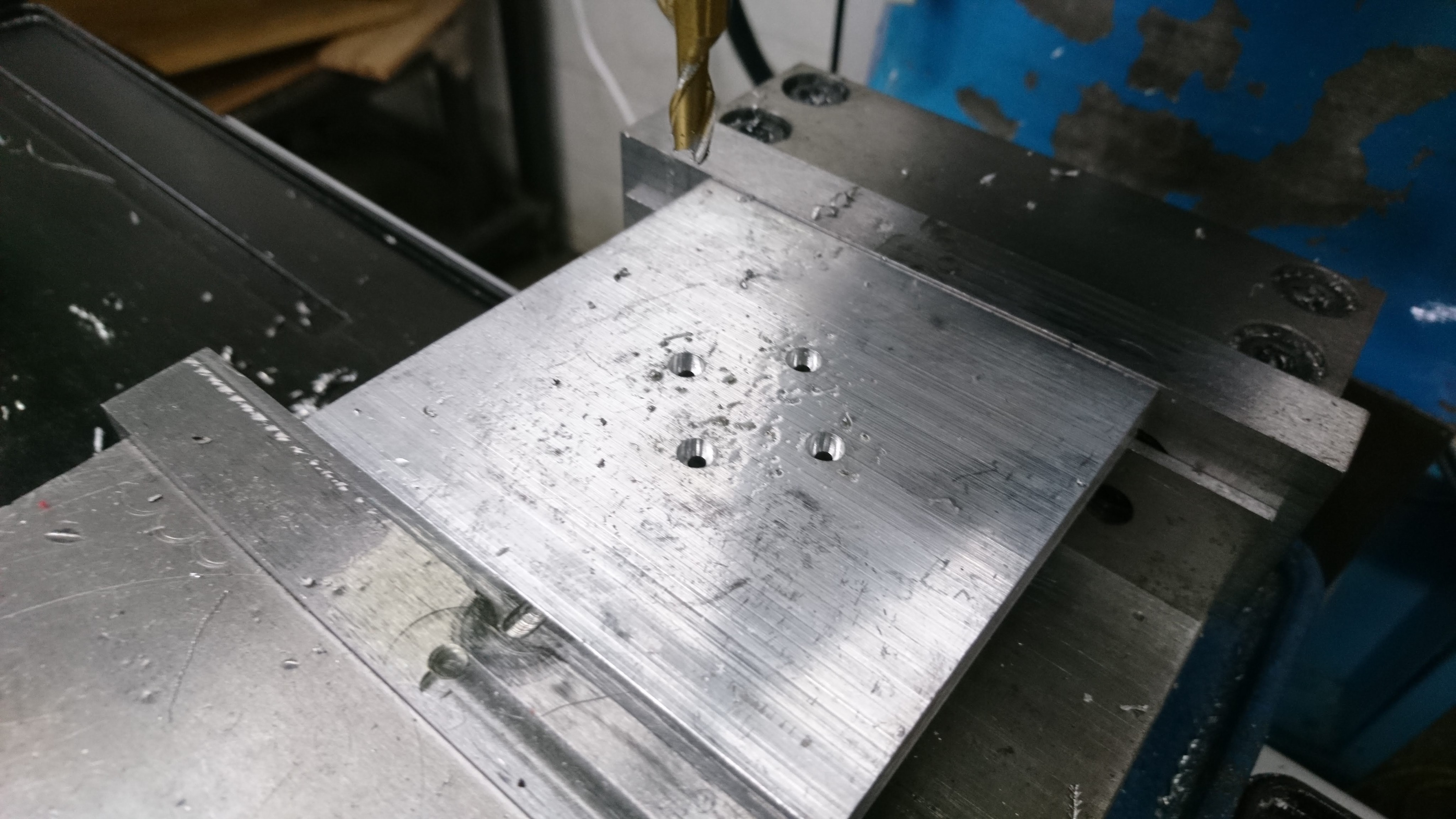

The old chassis was a single monolithic print that took about 35 hours of print time. Because of its monolithic nature, there were lots of interference problems during assembly. For instance, the shoulder motors could only have 4 of the 6 possible bolts installed, and 2 more of the bolts extended beyond the chassis entirely. I decided to break it up into multiple pieces, which uses a lot more inserts and bolts, but should allow for a feasible order of assembly and manageable repair.