New Mech Warfare turret

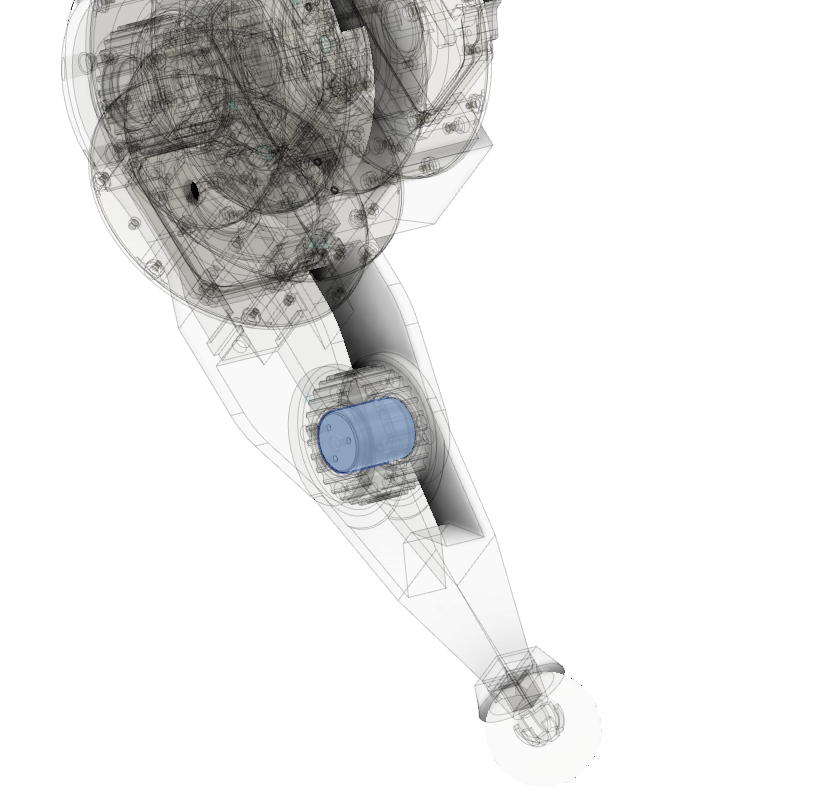

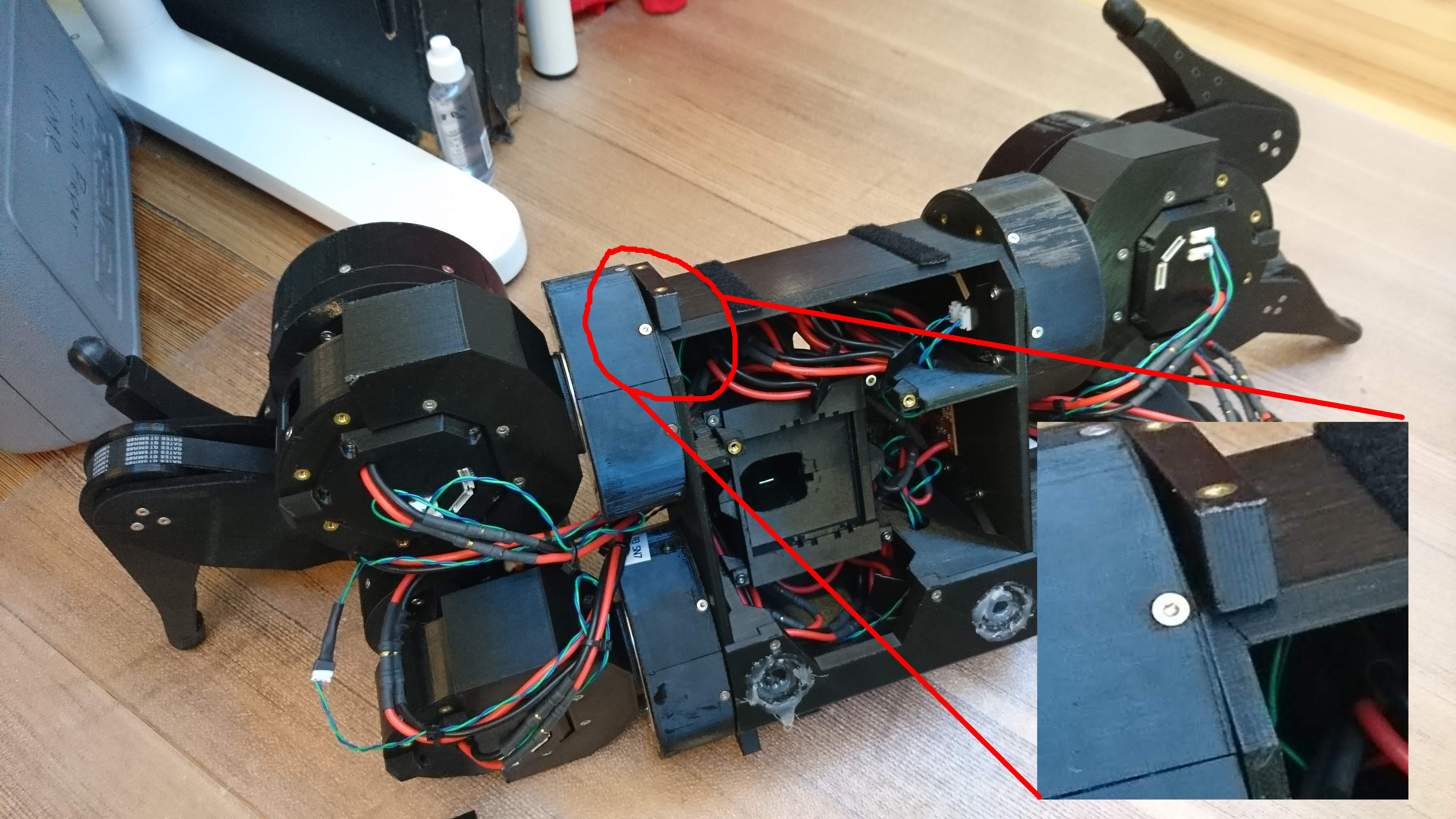

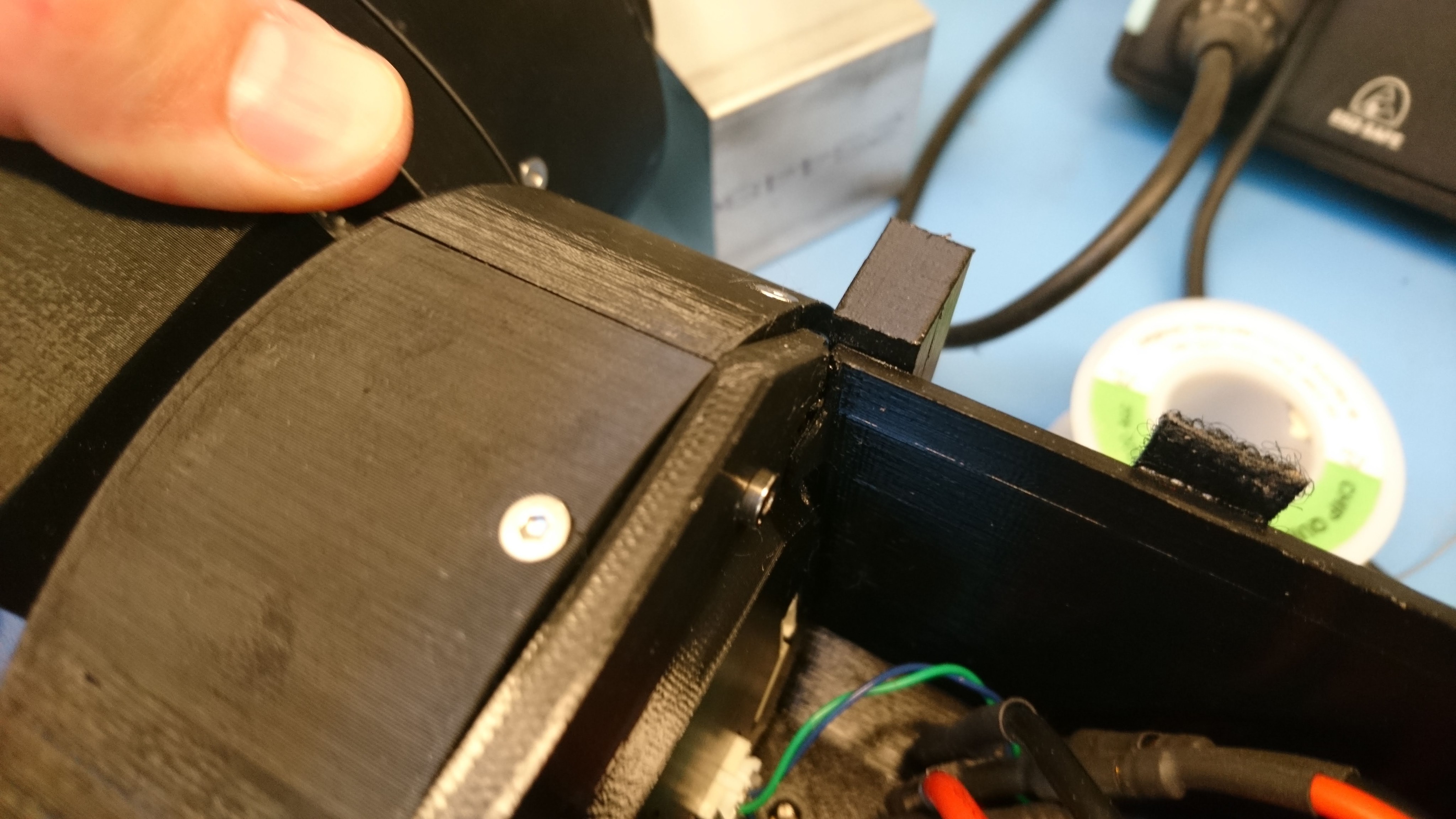

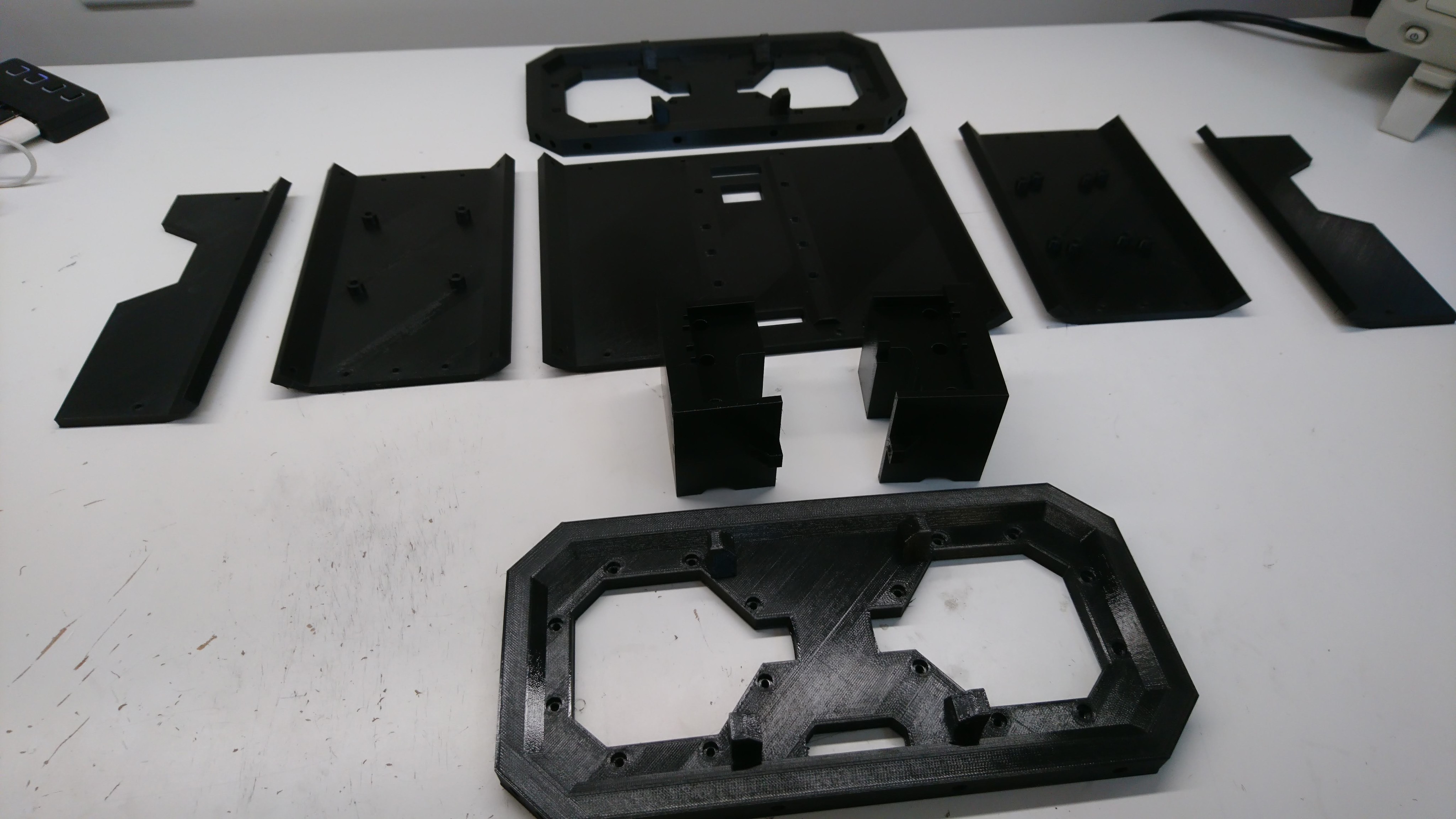

Another of the tasks I’ve set for myself with regards to future Mech Warfare competitions is redesigning the turret. The previous turret I built had some novel technical features, such as active inertial gimbal stabilization and automatic optical target tracking, however it had some problems too. The biggest one for my purposes now, was that it still used the old RS485 based protocol and not the new CAN-FD based one. Second, the turret had some dynamic stability and rigidity issues. The magazine consisted of an aluminum tube sticking out of the top which made the entire thing very top heavy. The 3d printed fork is the same I one I had made at Shapeways 5 years ago. It is amazingly flexible in the lateral direction, which results in a lot of undesired oscillation if the base platform isn’t perfectly stable. I’ve learned a lot about 3d printing and mechanical design in the meantime (but of course still have a seemingly infinite amount more to learn!) and think I can do better. Finally, cable management between the top and bottom was always challenging. You want to have a large range of motion, but keeping power and data flowing between the two rotating sections was never easy.