When using tview to monitor and control moteus controllers, there have

been a fair number of limitations and “gotchas”. One of the biggest

for newcomers is the distinction between error checking in the d pos

command, and faults that can occur during position mode itself. When

using the diagnostic protocol and issuing a command, for those

commands which direct moteus to perform some control action, the

controller will respond with an “OK” as long as the command itself is

syntactically correct. Only then is it submitted to the online

control loop, after which faults resulting from the command will

manifest as the controller reporting a mode of kFault or 1, with a

corresponding fault code. In the diagnostic tree view, those are

shown as servo_stats.mode and servo_stats.fault.

So, what many newcomers do is take a moteus board fresh from the factory, which starts with servopos.position_min=-0.01 and servopos.position_max=0.01, and do the following in order:

- Issue a totally reasonable command like

d pos nan 0 nan to command the motor to hold position

- Observe an OK come back

- Don’t see the motor do anything

What those users don’t realize is that in order to see why moteus doesn’t move, you need to look at the current reported mode and fault, not at the response over the diagnostic channel.

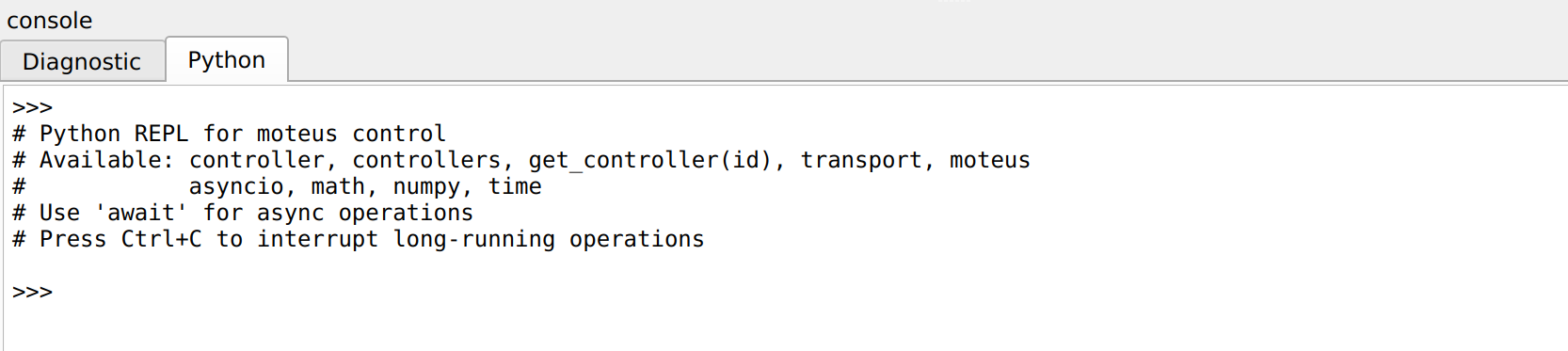

Here I’d like to describe a solution to this problem that hopefully makes tview much easier in general with fewer instances of confusion resulting.