Trotting with a flight phase

Here’s another short video only update, I’ve been experimenting with flight phases on the quad A1. With the gait formulation as I have it now, it isn’t terribly stable, but with some coaxing videos are possible:

Here’s another short video only update, I’ve been experimenting with flight phases on the quad A1. With the gait formulation as I have it now, it isn’t terribly stable, but with some coaxing videos are possible:

The moteus controller uses a DRV8323 smart driver IC to drive the power MOSFETs as well as provide various safety functions. One of the capabilities it has which has so far been unexplored in moteus is its ability to control the drive strength and dead time through software configuration.

In a switching power supply or switching motor inverter, MOSFETs are arranged in a half bridge configuration. Depending upon the type of converter, one or more half bridges are used (3 phase inverters like moteus use 3 of them). Each “half bridge” has two MOSFETs, one connected between positive power and the output terminal, and the other connected between the output terminal and ground.

I’m continuing to make progress with getting the quad A1 to move at higher speeds, furthering my earlier video update. I’ll write up more later, but here’s a quick snapshot showing a 2 m/s trot:

Recently I described some changes I made to improve the low speed torque ripple of the moteus controlle. I also built a dynamometer. I decided to use the dynamometer to quantify how much things had improved with the torque ripple, and to see how much room for improvement was left with any anti-cogging implementation.

Here, the test script is relatively simple. I have the “fixture” controller sweep at a very low velocity (0.01Hz) through a bit more than one full revolution using a relatively high I term in the PID controller to ensure that it really holds that position no matter what external torque is applied. Then, the “device under test” controller is just commanded either to be powered off, or in position mode with a pd gain of 0 and a feedforward torque. Then I can just measure the result from the torque transducer while this sweeps through a full revolution, and correlate the measured torque with the encoder position.

Recently dlickindorf pointed out in the mjbots discord that he was having problems with very low torques on his large PMSM hobby-grade motor. While moteus doesn’t have any anti-cogging support yet, it should still be capable of driving motors such that the unexpected torque isn’t much worse than the baseline cogging torque of the motor. However, he was seeing much worse behavior with controlling to 0 current, as much as a full percent of the maximum torque of the motor.

The moteus controller, uses an absolute magnetic encoder to sense the position of the rotor and thus be capable of field oriented control FOC of brushless motors. To date, all the iterations of the controller have used the AS5047P encoder from ams. This is relatively common, works fine over SPI and hasn’t caused any problems. While investigating some other issues, I decided to take a stab at trying some alternate encoders. First, I tried the AS5047U, which is the same basic encoder, but incorporates a digital filter. I also tried the MA732, from Monolithic Power, which uses a different operating principle and also includes a digital filter. The plus side of the MA732 is that it reports full 16 bit values, even if not all of them provide a lot of value.

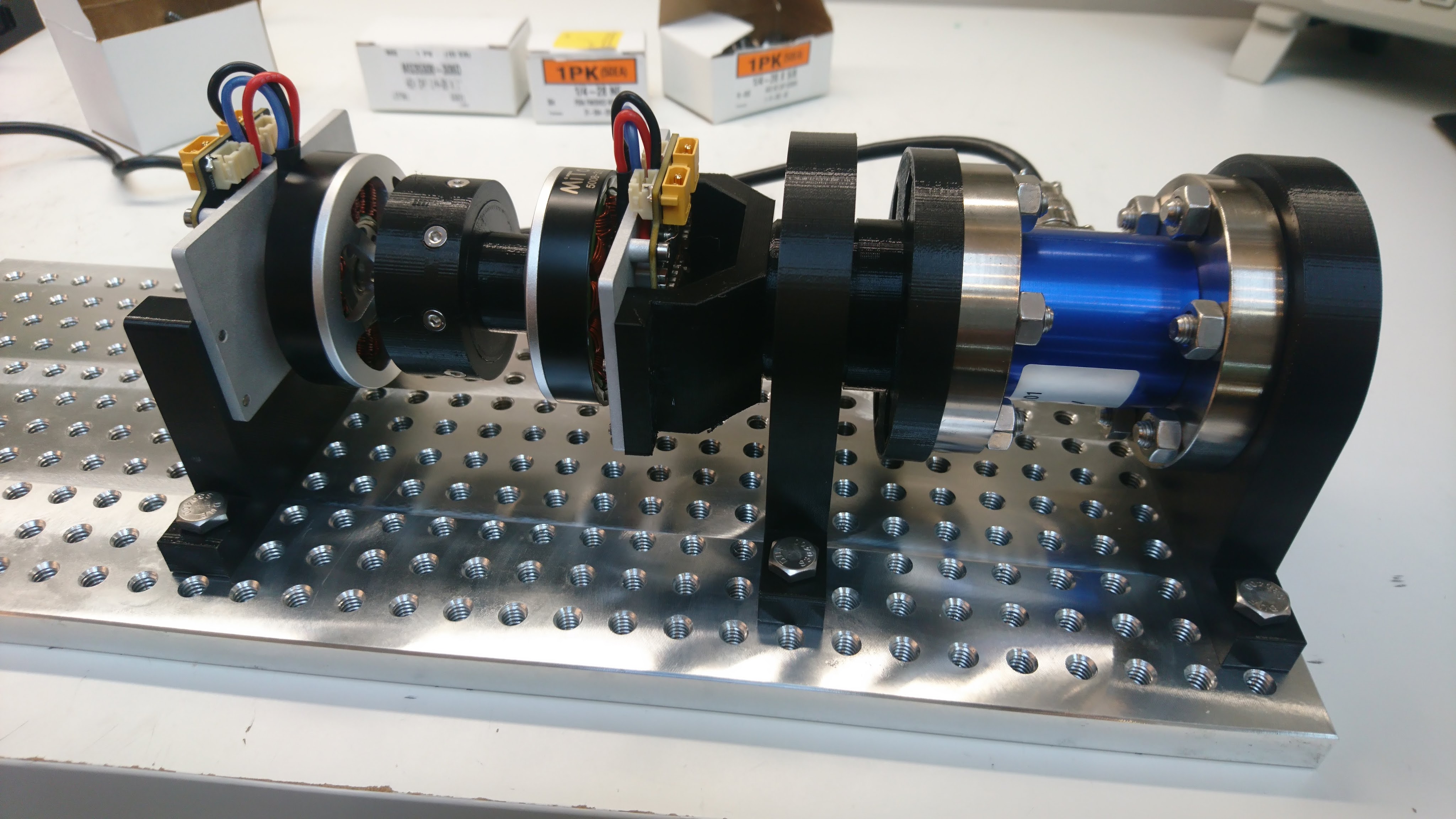

Earlier I showed off a torque transducer and the calibration fixture I used for it. I’ve now got enough assembled to make an entire dynamometer:

This has the torque transducer on one end, coupled to the “fixture” moteus controller through a bearing support. Then that is connected via a 3d printed coupler to the “device under test” moteus controller, which is hard mounted to the base plate. Any net torque between the two controllers will be coupled back to the transducer resulting in a measured torque.

In another discord moment, someone was asking about the difference between electrolytic capacitors and multi-layer ceramic capacitors. That, plus some desire to re-rate the moteus, inspired me to do another sweep and measure the DC bus voltage ripple for various power levels. I captured this plot with a 24V power supply, with a 5008 motor with 0.061 ohm of winding resistance or so, and each current being applied for 300ms. The voltage ripple is peak to peak measured at the power connector.

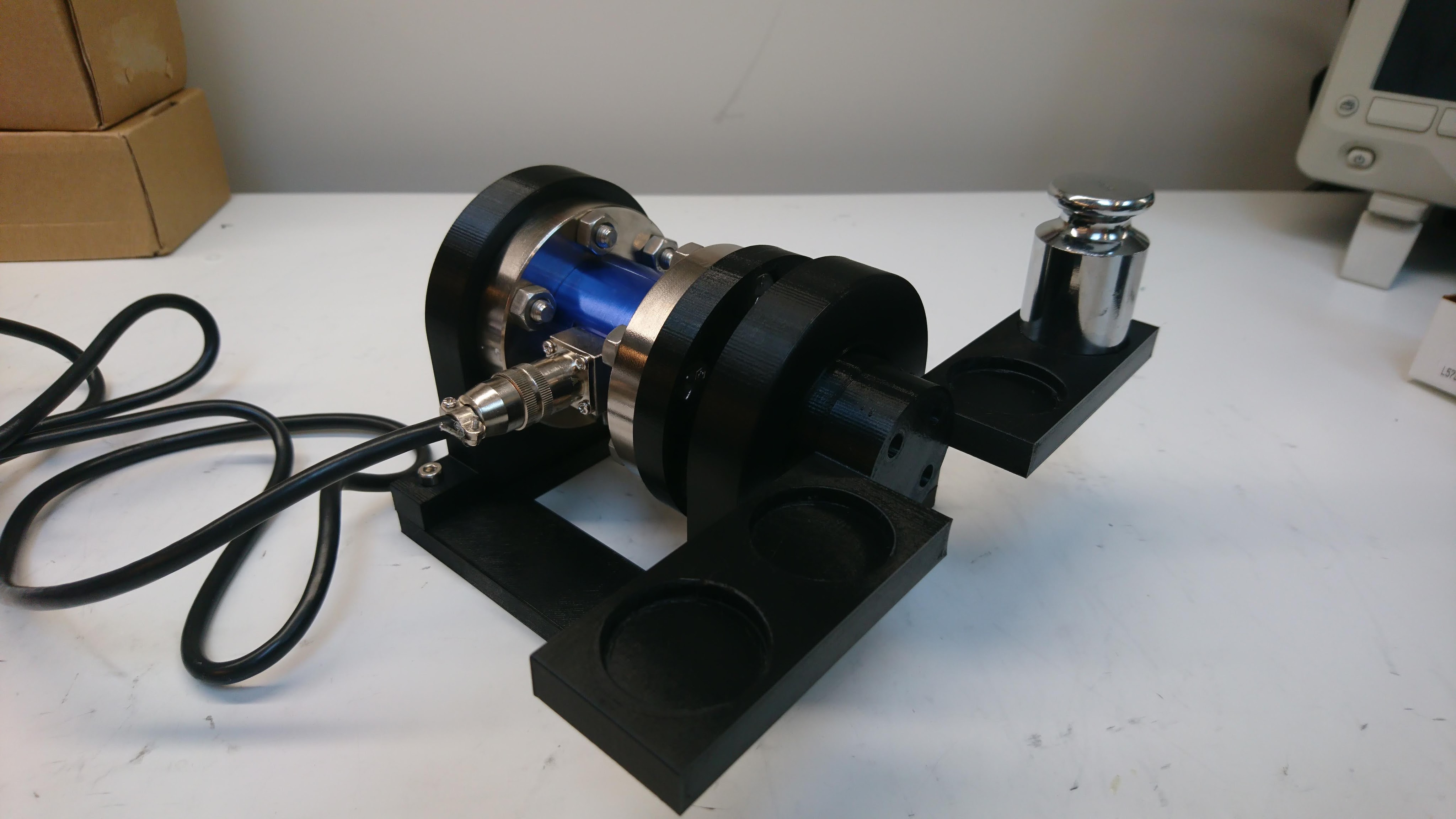

I’ve been wanting to build a dynamometer for a while to better characterize the performance of the direct drive and geared versions of the moteus controller. I have now started down that path with a torque transducer, which I calibrated with the below fixture:

I got a what ended up being a low quality load cell amplifier to use with it from the same supplier, although discovered it was total garbage and am now using a SparkFun OpenScale board which seems to be working much better. Soon I’ll hopefully have something wired up that actually has a controller or two on it.

I’ve started some development on higher speed gaits for the quad A1! No real details to report now, just a video showing the first time I tested it not in simulation. I will admit these clips were cherry-picked, as there are problems still, but it is a start!