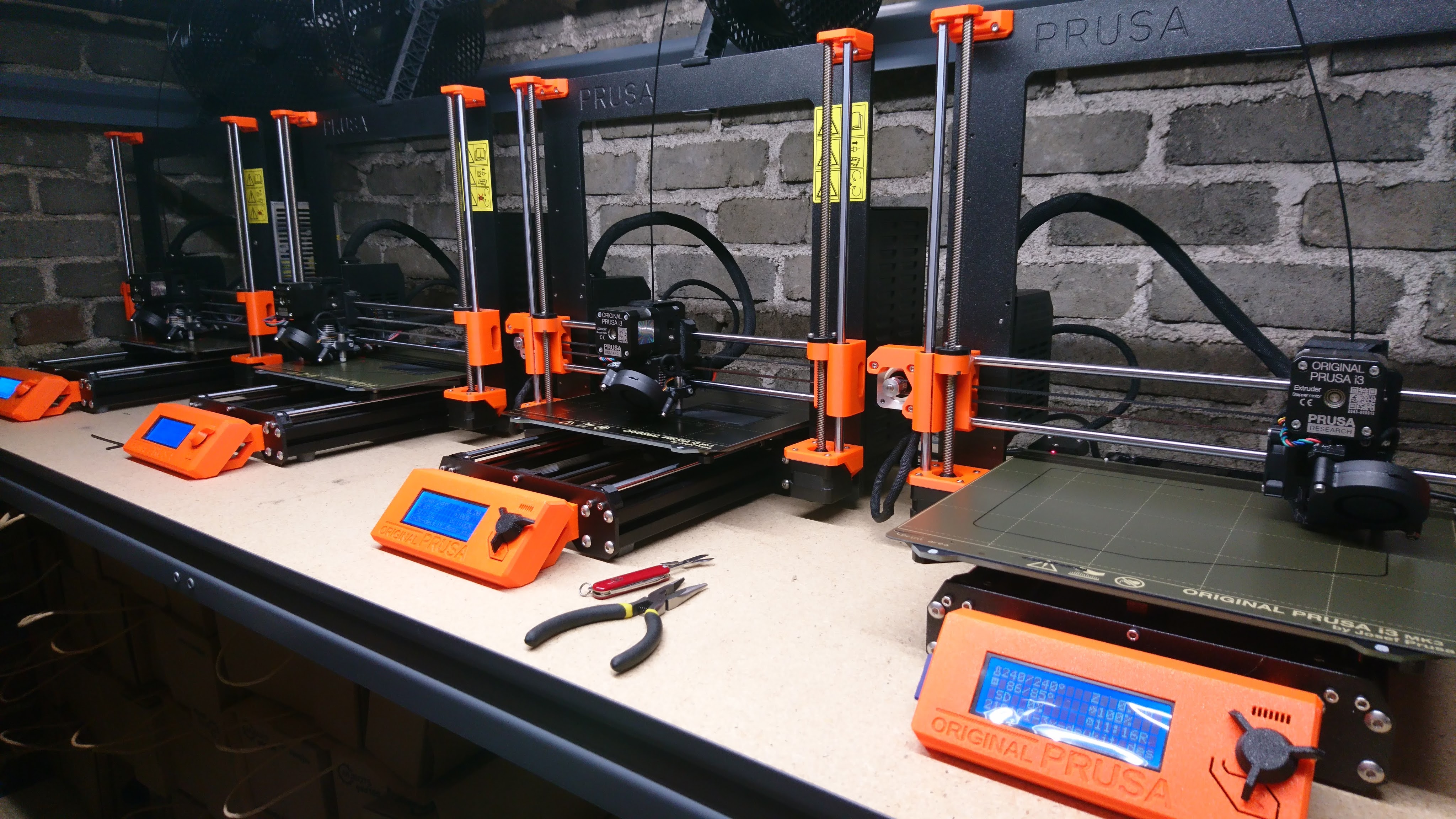

Fixing a chip evacuation problem on the Pocket NC

My Pocket NC v2-50 is a fine machine for its size class, but there are still plenty of annoyances. One of them is that chips can accumulate places they shouldn’t, either during a run, or over the long term.

There is a cavity near the back of the machine where the Y axis cables and cable guide retract into. That cavity is exposed to chips flying around, so they tend to accumulate there. There is a hole in the bottom of the machine where the chips could maybe fall out, except the hole is too small for any but the smallest of chips, and further, it is completely sealed off when mounted in the stock Pocket NC enclosure.