Pinions, set screws, and glue

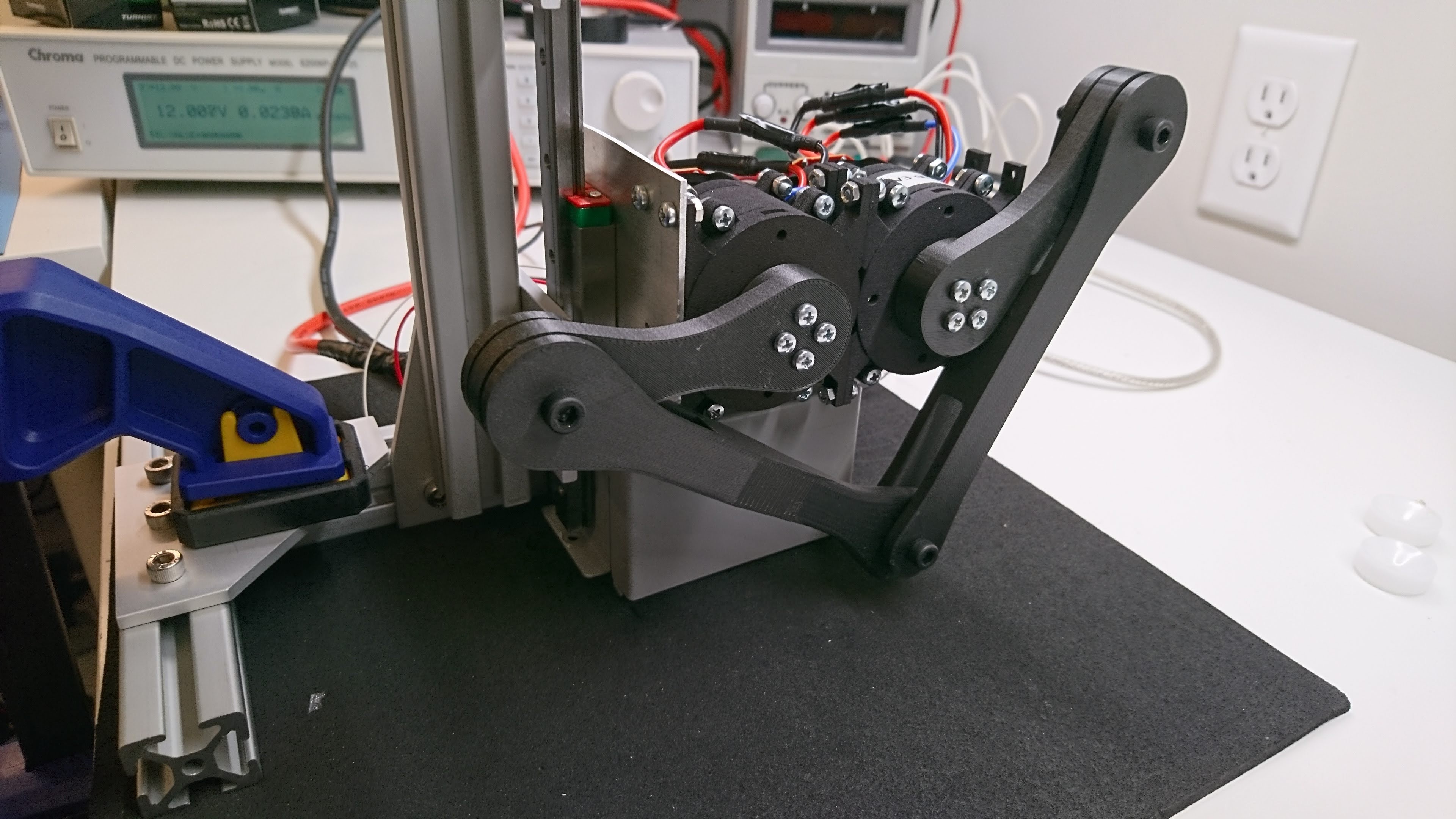

One of my intermediate goals for building new actuators for SMMB is to get them robust enough to jump continuously for some duration of time. Progress is slow, as things break, new parts are ordered, repairs are made, and jumping resumes. The most recent failure is at least interesting enough to me that it is worth writing up.

To recap, I’m building a brushless servo based around a Turnigy Elite 3508 brushless motor and a custom 5x planetary gearbox. The 3508 is intended for quadcopter applications, so to install a spur gear I first extracted the original shaft, then pressed in a new shaft with two flats on it. One flat for the set screw attaching the rotor to the shaft (which had a press fit), and a second for the set screw attaching the spur gear to the output of the shaft.