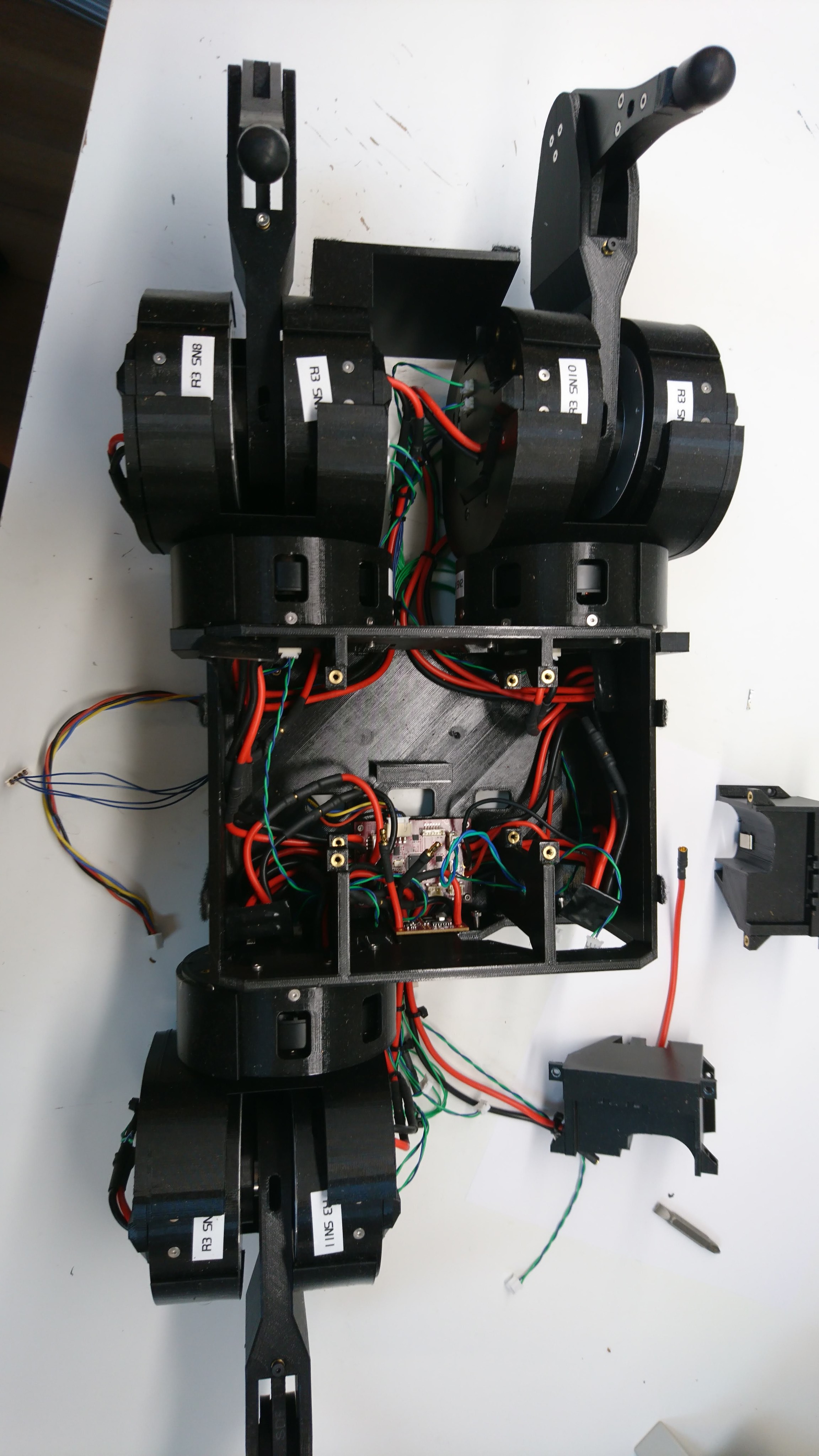

Stripping the coaxial quadruped for parts

To switch to the full rotation gear design, I needed to get all my gearbox motors, some bearings, and a lot of other bits and pieces disassembled and ready for re-use.

The remaining 3 non-broken legs from Maker Faire

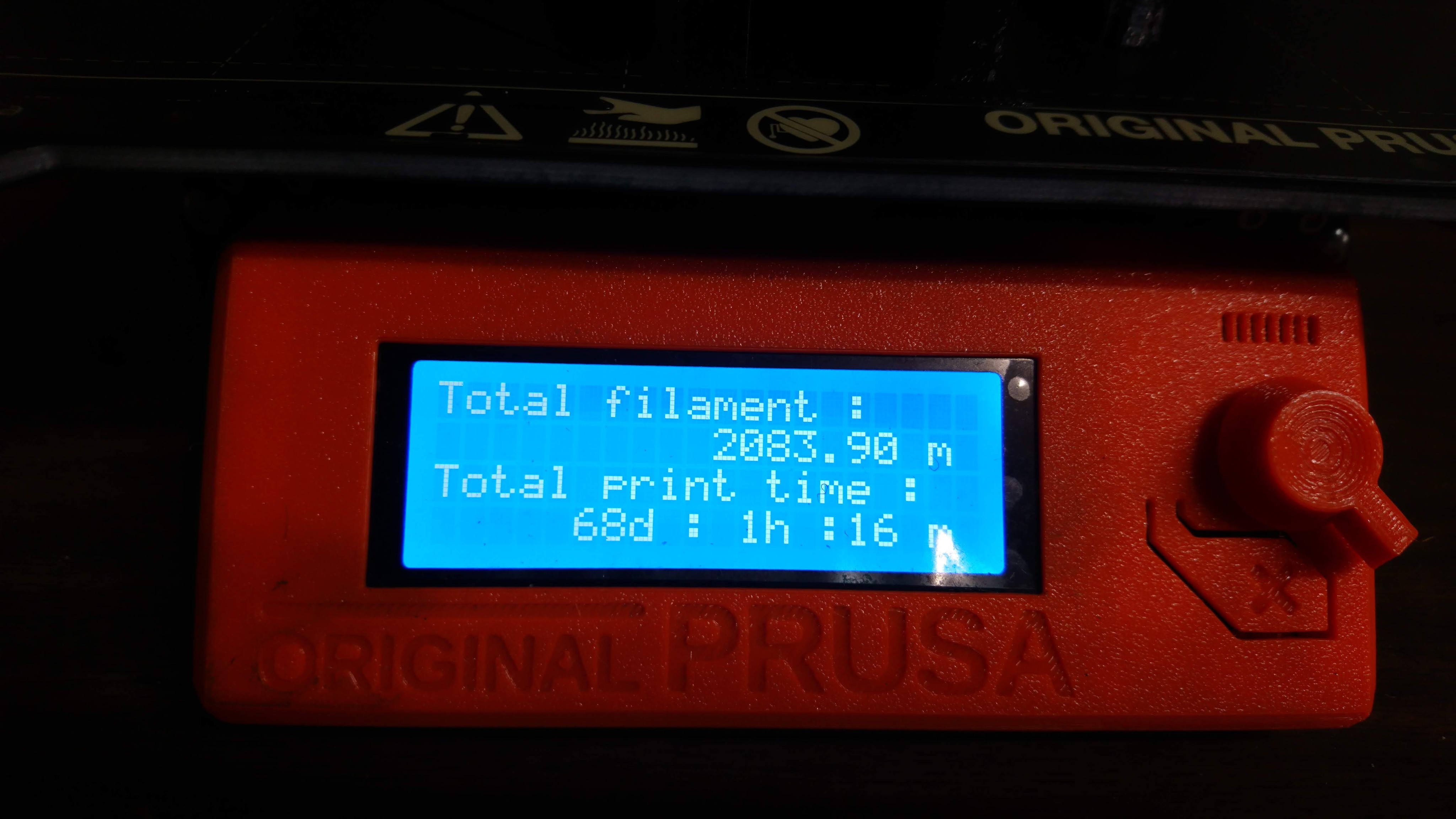

Taking everything apart took a surprising amount of time, nearly a full day. Each leg resulted in quite a collection of fasteners. Seeing them all in one place made me realize how complex this has become!