Improving the moteus update rate, part 1

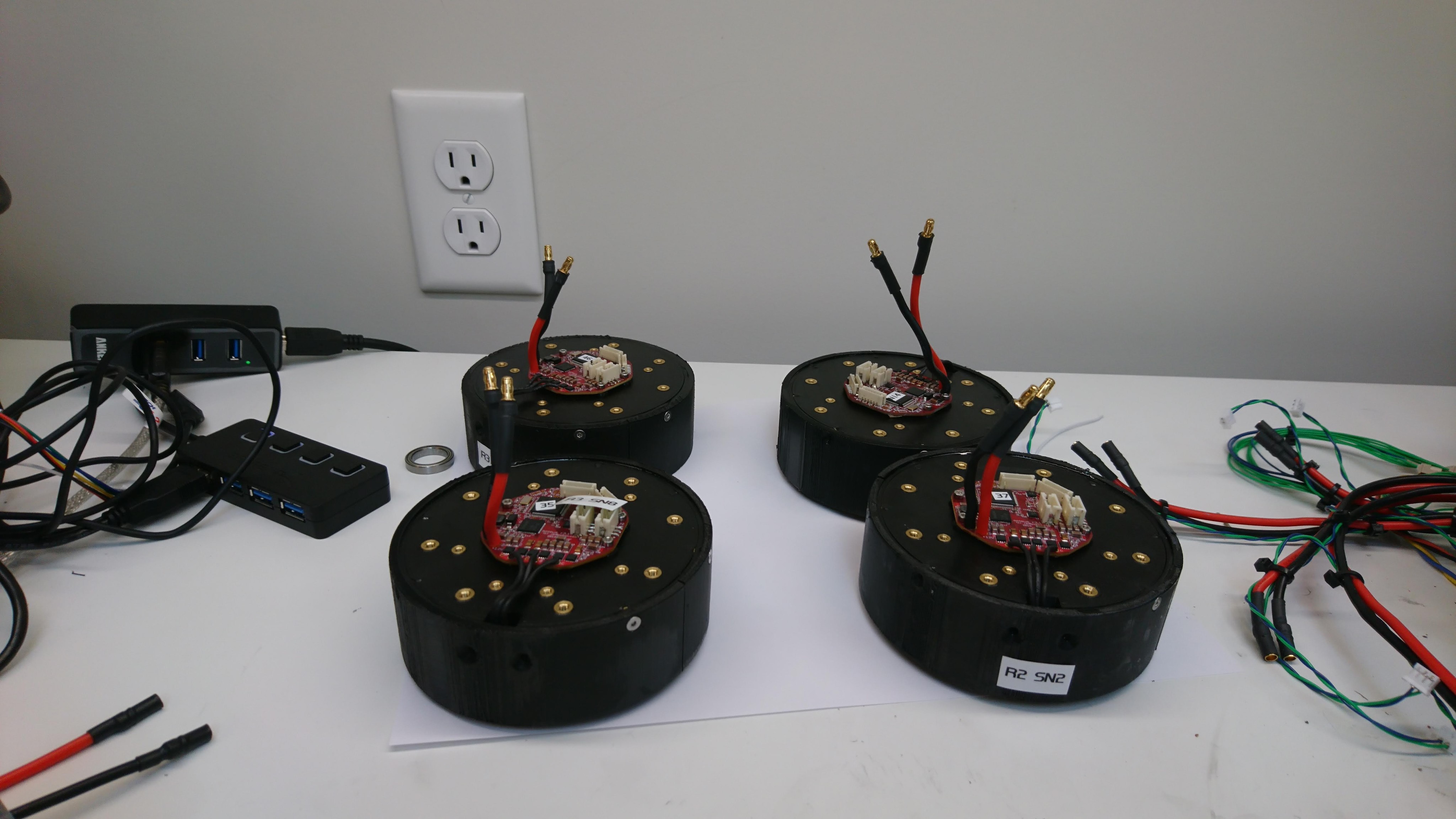

The moteus brushless controller I’ve developed for the force controlled quadruped uses an RS485 based command-response communication protocol. To complete a full control cycle, the controlling computer needs to send new commands to each servo and read the current state back from each of them. While I designed the system to be capable of high rate all-system updates, my initial implementation took a lot of shortcuts. The result being that for all my testing so far, the outgoing update rate has been 100Hz, but state read back from the servos has been more at like 10Hz. Here I’ll cover my work to get that rate both symmetric, and higher.