Preparing stock on a CNC Bridgeport

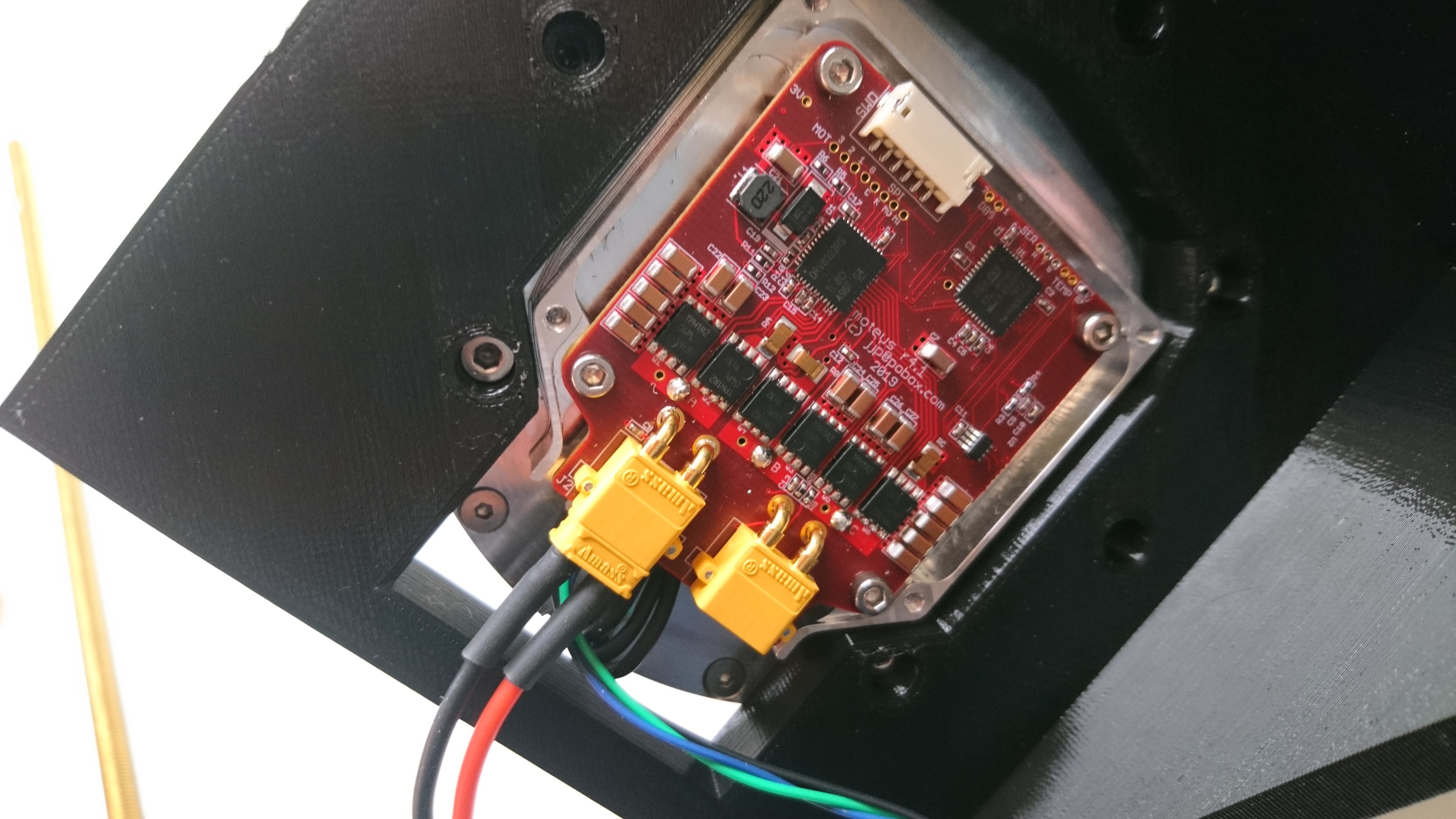

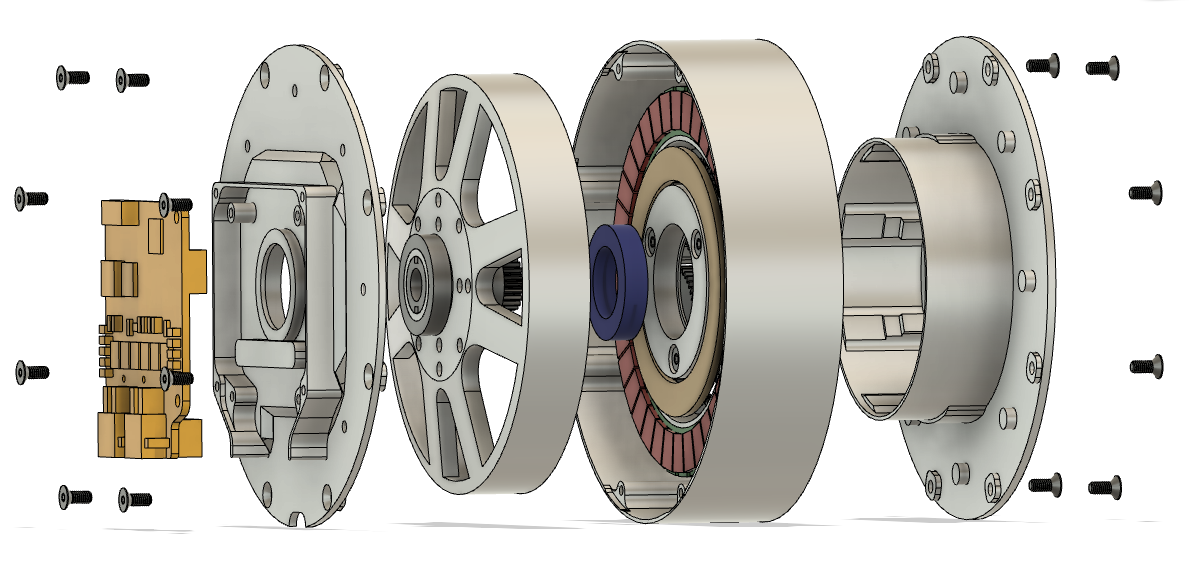

As mentioned previously, I made up some soft jaws to hold 4in round stock in a 6" vise. My goal was to prepare stock for workholding on the Pocket NC v2-50 to machine prototypes of the front and back housing for the reduced weight moteus servo mk2.

Now, I’ve used those soft jaws to trim down both pieces of stock to the correct length, bore a center hole, and in the case of the front housing, remove a bunch of additional material in a more expeditious manner. There’s not much more to it than that, so here’s the video: