Auxiliary encoders for moteus

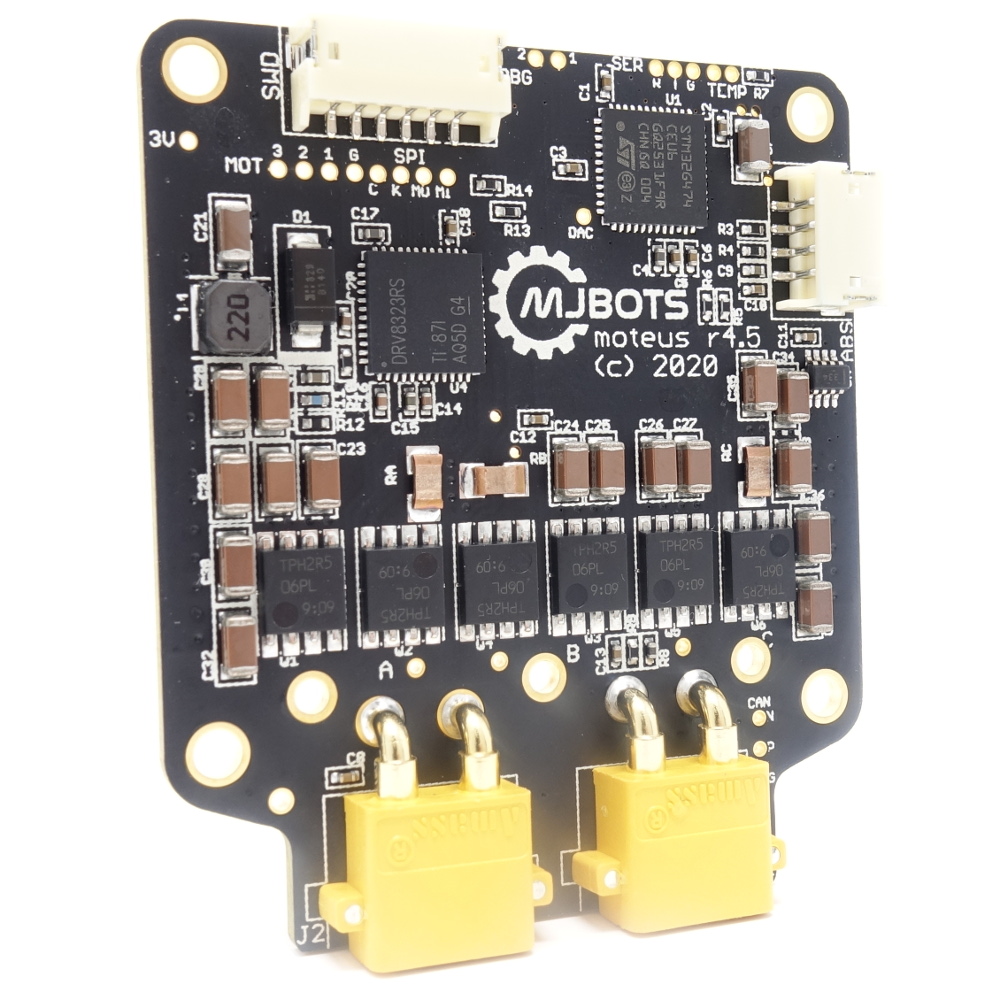

The moteus controller uses an absolute magnetic encoder to sense the position of the rotor in order to conduct field oriented control of the motor. In many applications, this sensing is also sufficient to measure the output as well, particularly in direct drive applications. However, if the controller is driving the output through a gear reduction, multiple turns of the input are necessary to make one turn on the output. At power on, this results in an ambiguity, where the controller doesn’t know where the output is.