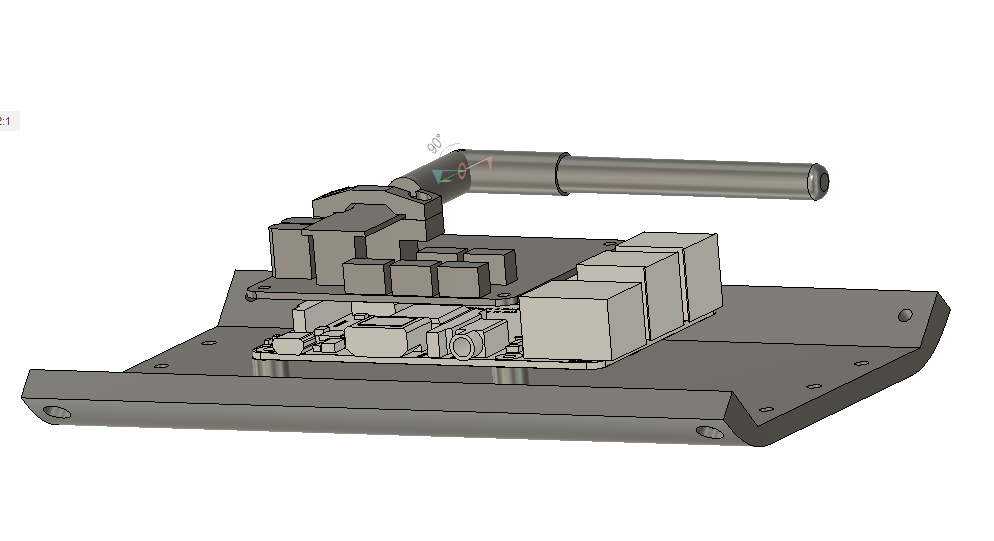

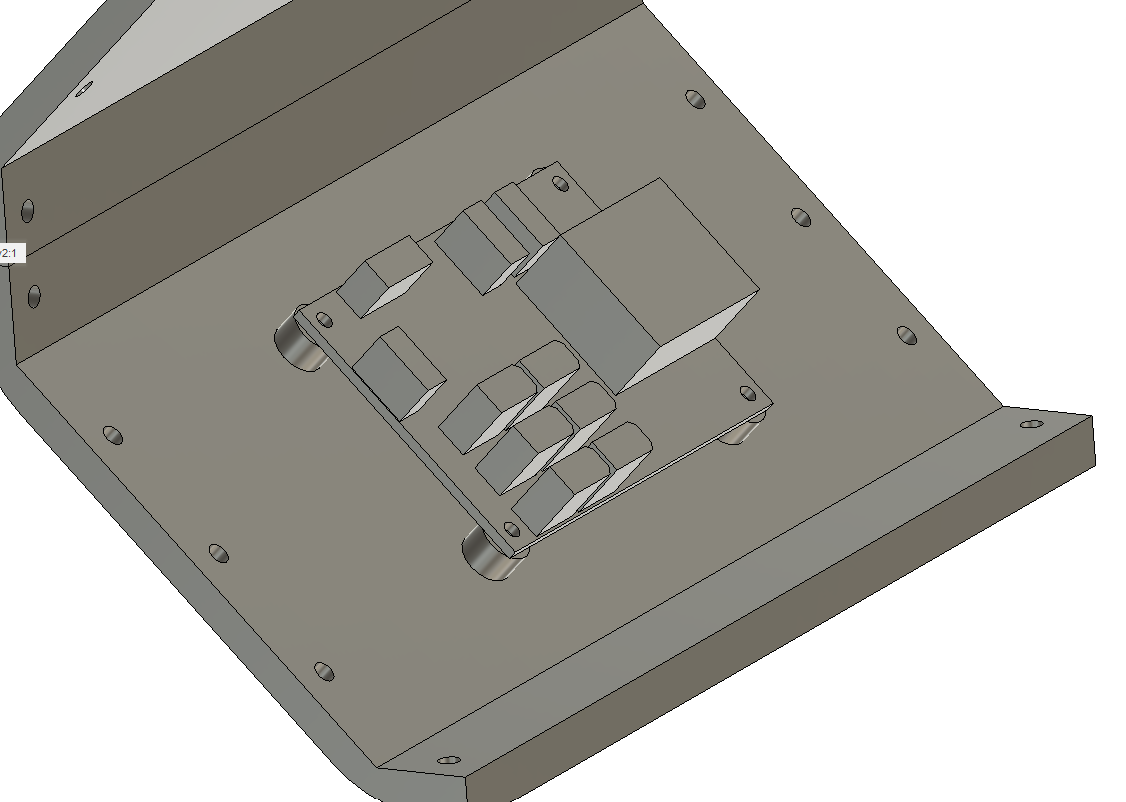

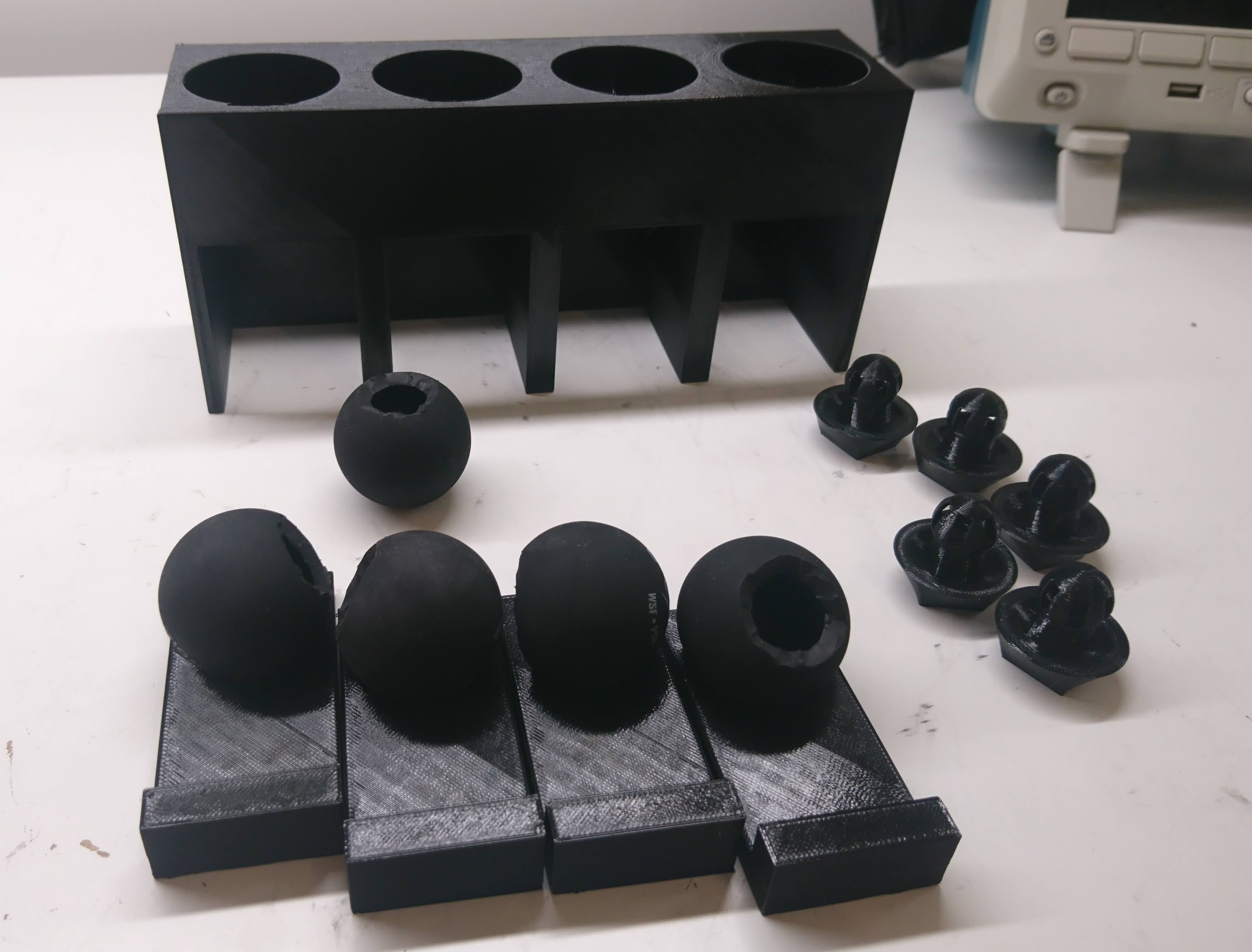

Quad feet construction fixture

The quad A1 was the first robot I built with foam cast feet. When I did the first feet, I jury rigged a fixture from some old toilet paper rolls to hold things in place while they were curing. When I went to rebuild with my most recent leg geometry, I figured it was time to get at least a little more serious. Thus, my new leg casting fixture:

When an insert is cast into place, it is set on one of the trays, the tray is inserted into a slot, and then a weight can be placed on top and constrained by the fixture.