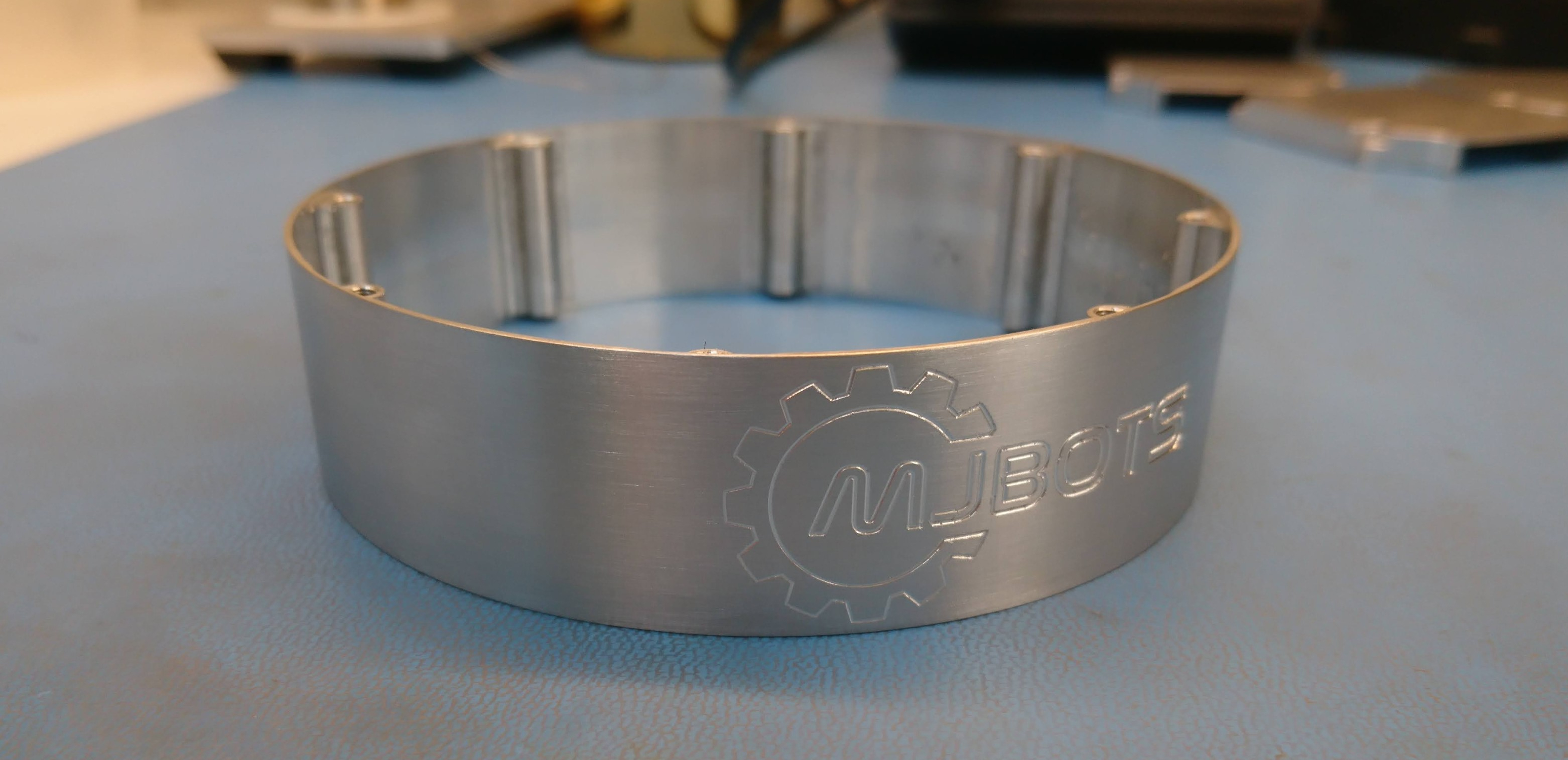

fdcanusb up at mjbots.com

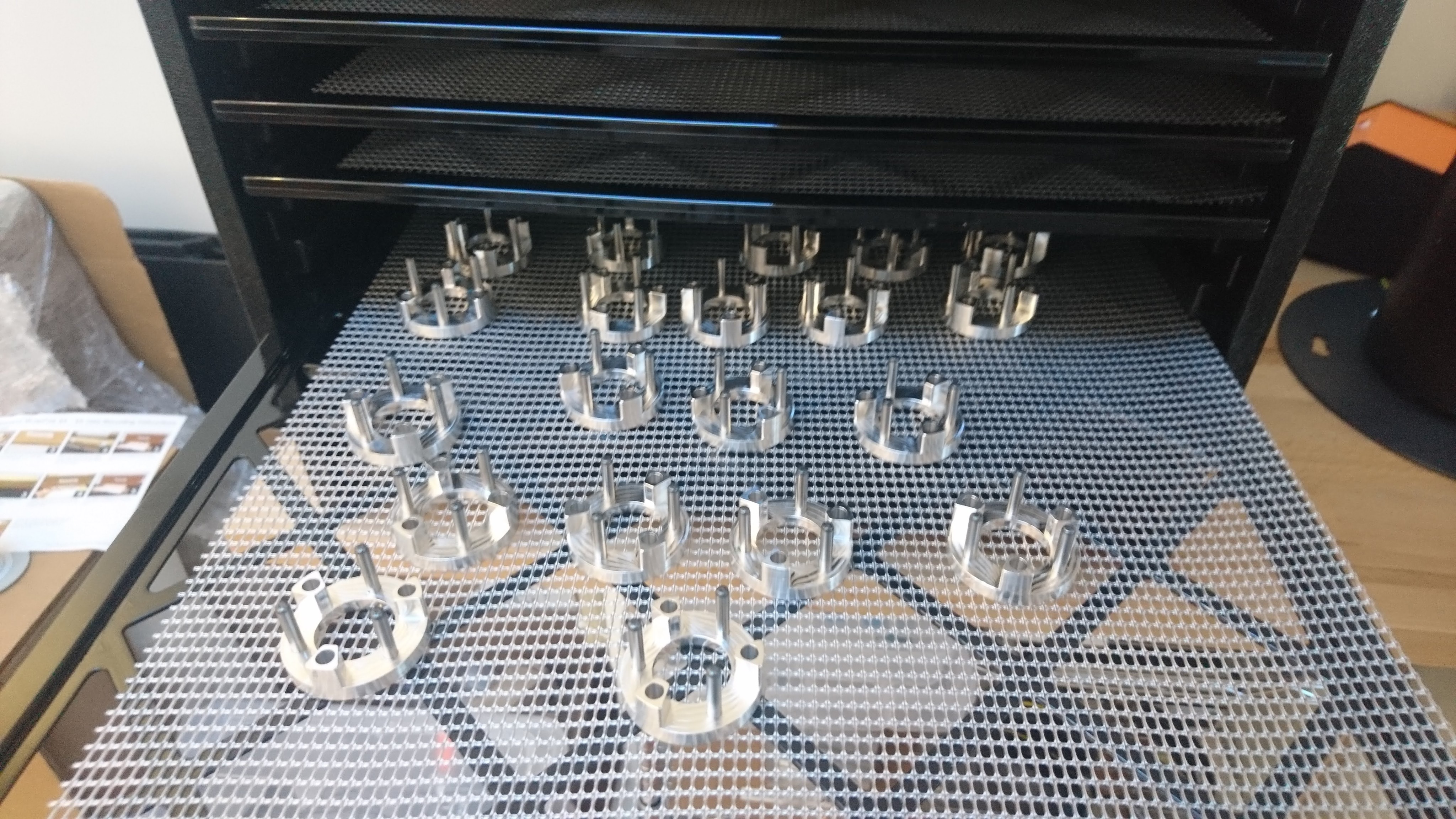

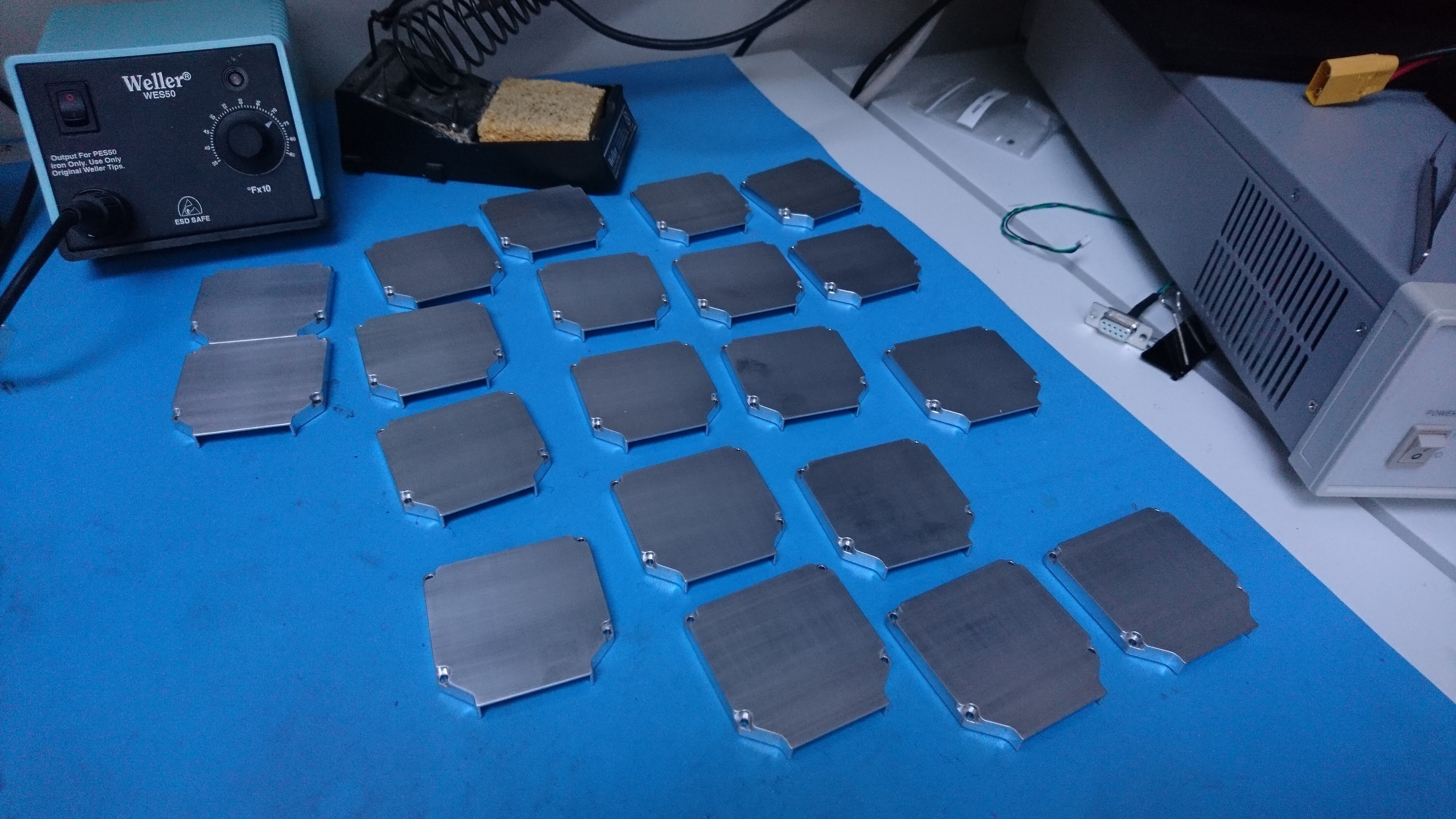

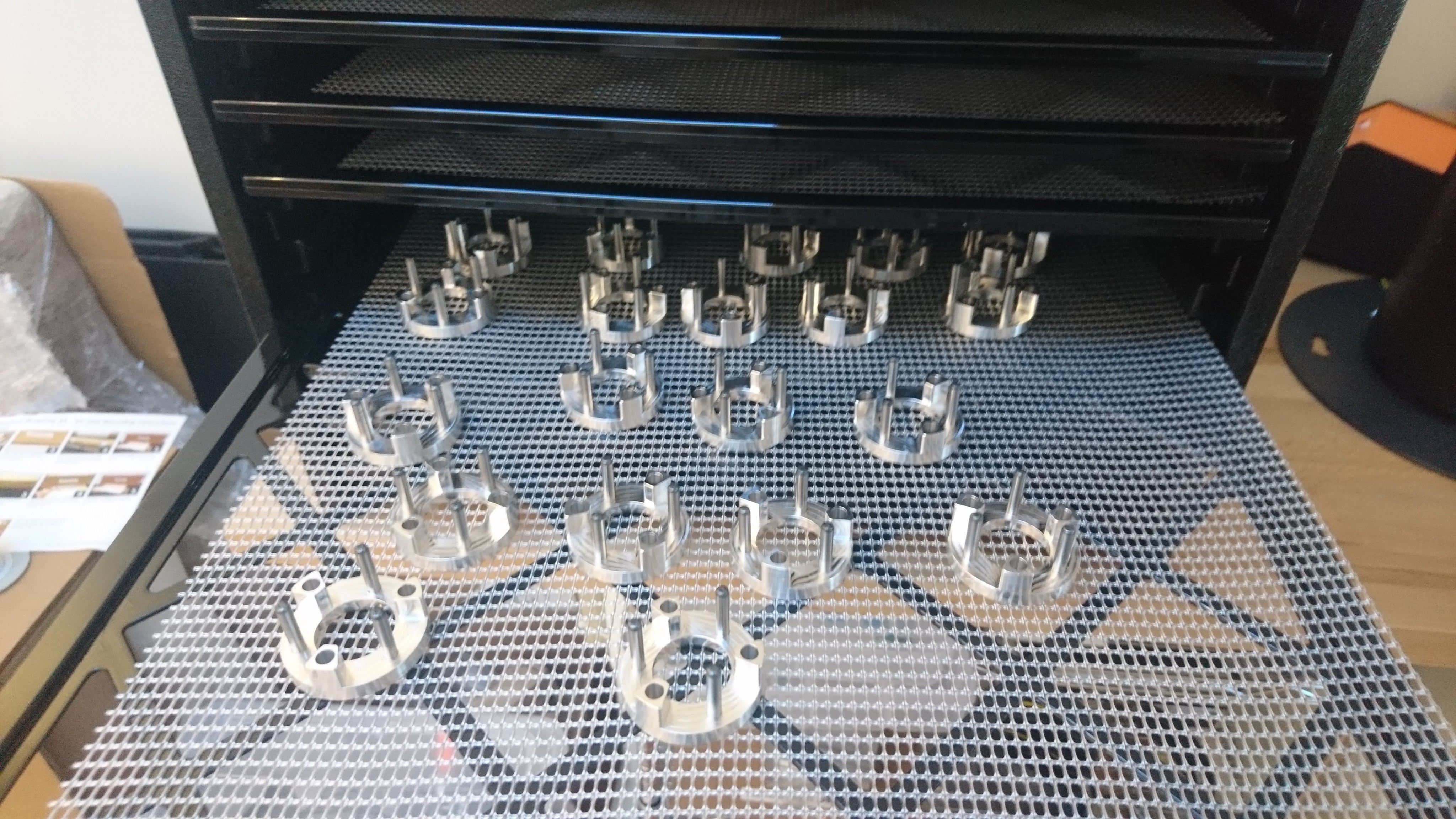

I’ve received my first production run of the fdcanusb CAN-FD USB adapters and they are up for sale at mjbots.com!

While this is necessary for interacting with the moteus controller, it is also a fine general purpose CAN-FD adapter. At the moment, the USB interface is a platform independent line based serial one (Windows, Linux, MacOS). It doesn’t yet interoperate with SocketCAN on linux, but hopefully that will be resolved in the not too distant future.