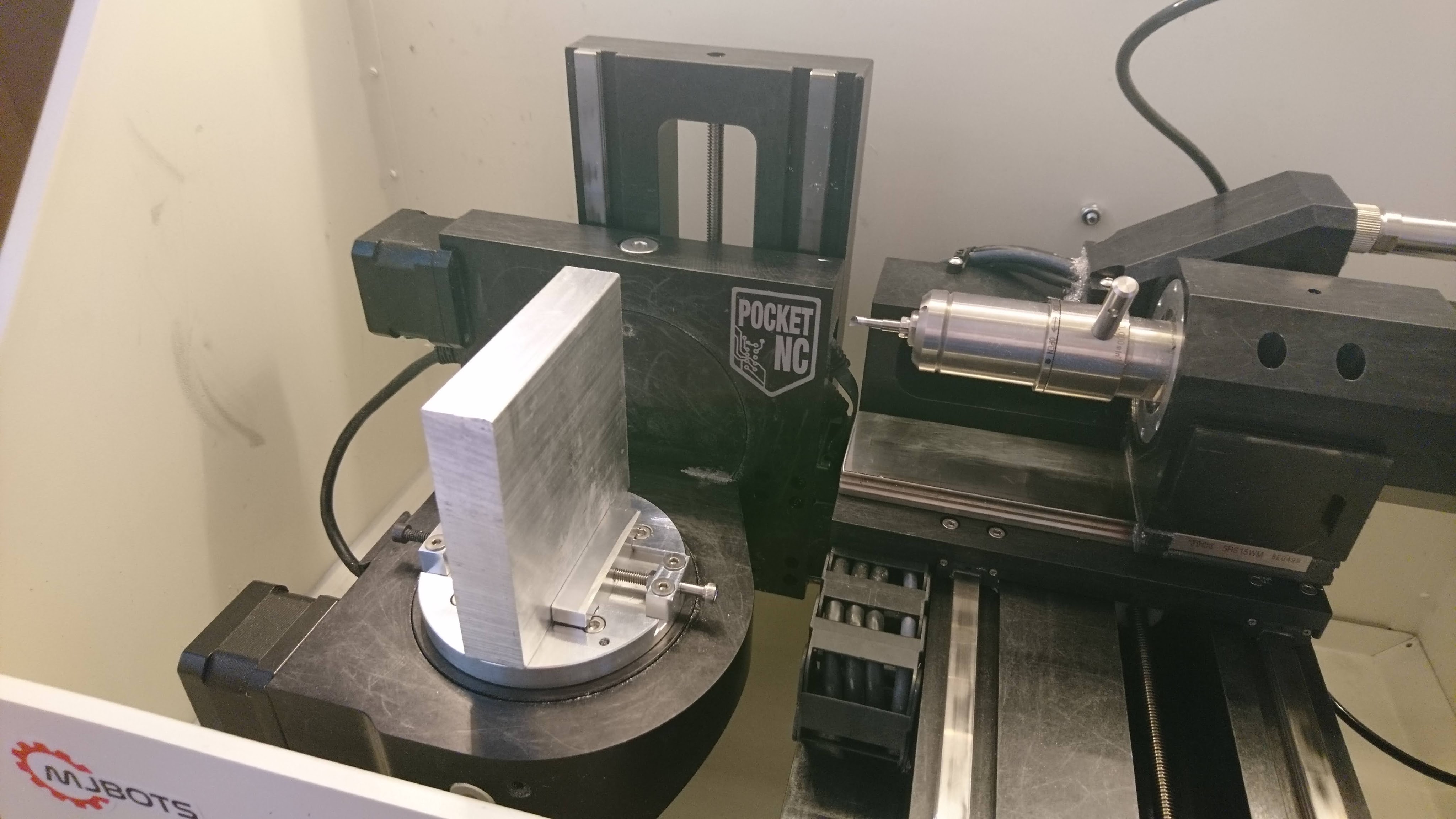

Pocket NC windowed machining

When I first acquired my Pocket NC v2-50, I was planning on using it for rapid prototyping of small aluminum parts. I figured with 5 axes, I could do many things with a single setup just clamping from the bottom. However, I was initially thwarted in that plan and had to resort to more creative workholding solutions due to two problems.

First was the vice that came with the Pocket NC. It is serviceable, but provides very little clamping force if you want to hold something that is tall and skinny. For now, while it isn’t ideal, I’m making good progress with the wcubed vise.

Second was the range of Z travel. As shipped by Pocket NC, in order to reach the center of rotation, tools have to stick out something like 35mm. If you want to go beyond, that adds even more. This was a problem, as there aren’t that many tools that can achieve a reasonable material removal rate while sticking out that far, if they can do so at all. This, I’ve finally resolved with this Pocket NC “Q-Tip”:

With that modification, I got an extra ~15mm of travel, which means that I can reach the center of rotation with only 18mm of stickout which is completely reasonable for this class of tools.

Now I can finally “window” machine parts out of a few maximally sized generic blocks of stock with only a single setup. I’ve got 3.5"x3.5" stock in a variety of thicknesses, which lets me do just about anything, if slowly, without having to worry about workholding.

That’s what it started with

And some video showing the cutting: